Company News

Jun 23, 2025

Engineering Journeys: Talia Babich & Lucy Wang on Passion, Progress, and Purpose

June 23 marks International Women in Engineering Day, a global celebration of…

Read MoreOur team has a relentless focus on continuous improvement in our design, manufacturing and delivery, and we’ve built our organizational processes to support the needs of our OEM partners and customers.

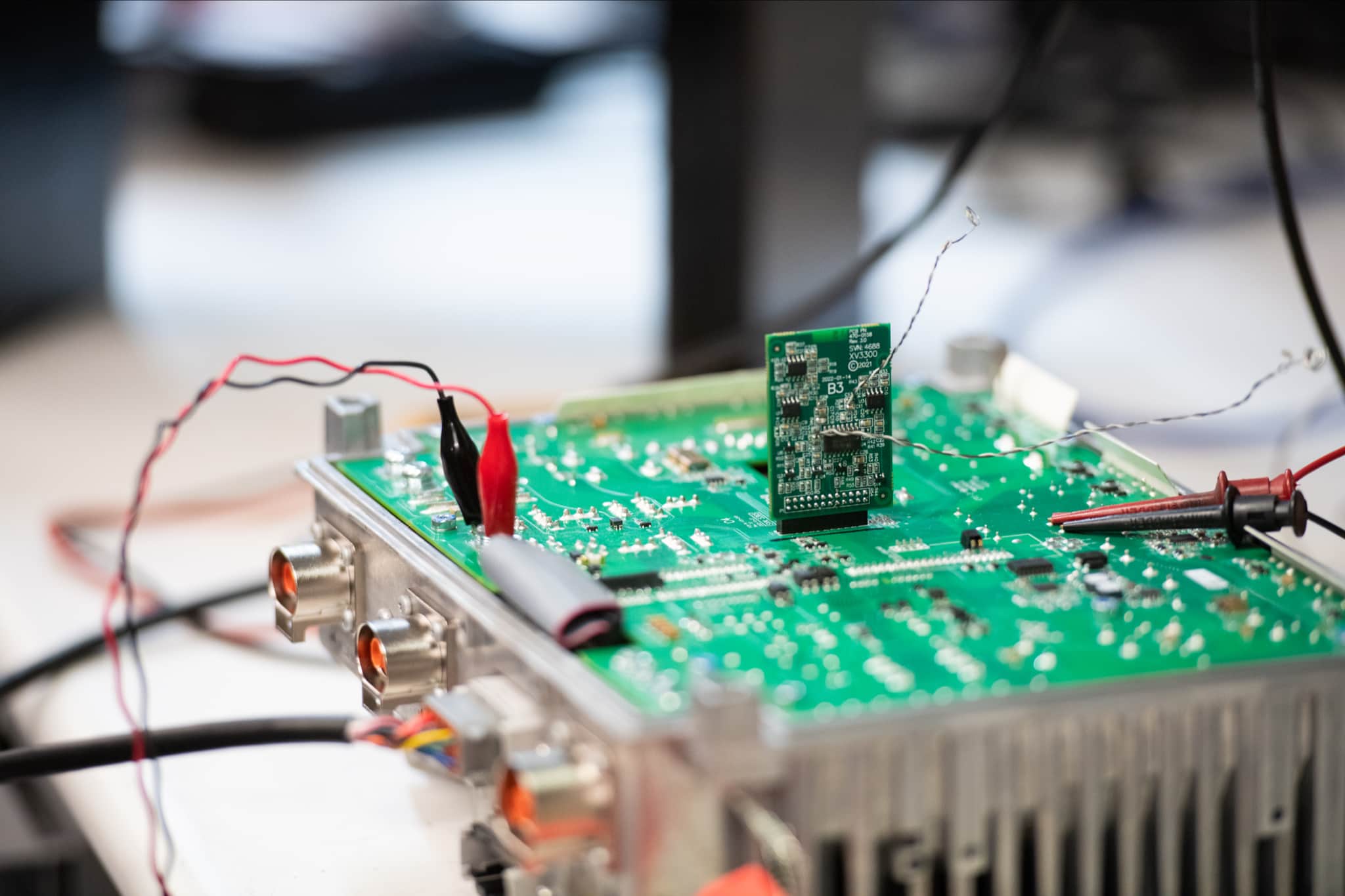

Our experienced engineers merge power electronics mechanical design and embedded software to create tailored and robust charging solutions for your electric vehicle applications.

Our approach is to support you every step of the way by assessing your specific needs, designing and implement the ideal solution, with access to after-sales support.

Delta-Q’s LEAN, automotive-grade manufacturing operations and experienced team enables us to build competitive products and fulfill consistent on-time delivery.

Our experienced engineering and software teams work with you to assess your product specification needs. We then design and implement a custom charging solution that conforms to the operating conditions that your customer’s machines face in the field.

We work closely with our battery partners and OEM customers to develop charging solutions designed and tested for maximum reliability in the harshest environments. All Delta-Q charger hardware and software undergoes a rigorous design and testing process, in our state-of-the-art power, temperature and automated climate-controlled battery test labs.

Delta-Q invests deeply in power electronics research with a dedicated R&D team focused on merging the latest technology developments and industry trends. We have several ongoing research projects, many peer-reviewed technical papers published in IEEE conferences and journals, and over eight product patents.

Delta-Q is more than just a charger supplier; we are your long-term strategic partner. Our global team is dedicated to helping our customers find the right charger configuration, and assist with the integration, training and servicing.

Delta-Q’s manufacturing and supply chain are world-class, LEAN, efficient and innovative. With a global automotive-grade manufacturing facility, and experienced operations and OEM support services team, we can offer our products at competitive price points, deliver products on time, and quickly respond and work in the field.

Learn more about how we use innovation and experience to meet our clients’ goals.

June 23 marks International Women in Engineering Day, a global celebration of…

Read MoreVancouver, BC – June 9, 2025 – Delta-Q Technologies (Delta-Q), a leading…

Read MoreFrom construction equipment to mobile elevated work platforms (MEWP), the electrification of…

Read More