Our commitment to sustainability goes beyond the lab and the manufacturing floor. Our company culture is steeped in an awareness of our planet’s energy challenges and a subsequent desire to be part of the solution. We do not use conflict minerals/metals to formulate any our products and those substances are not known to be present in any of the raw materials we use to make our products.

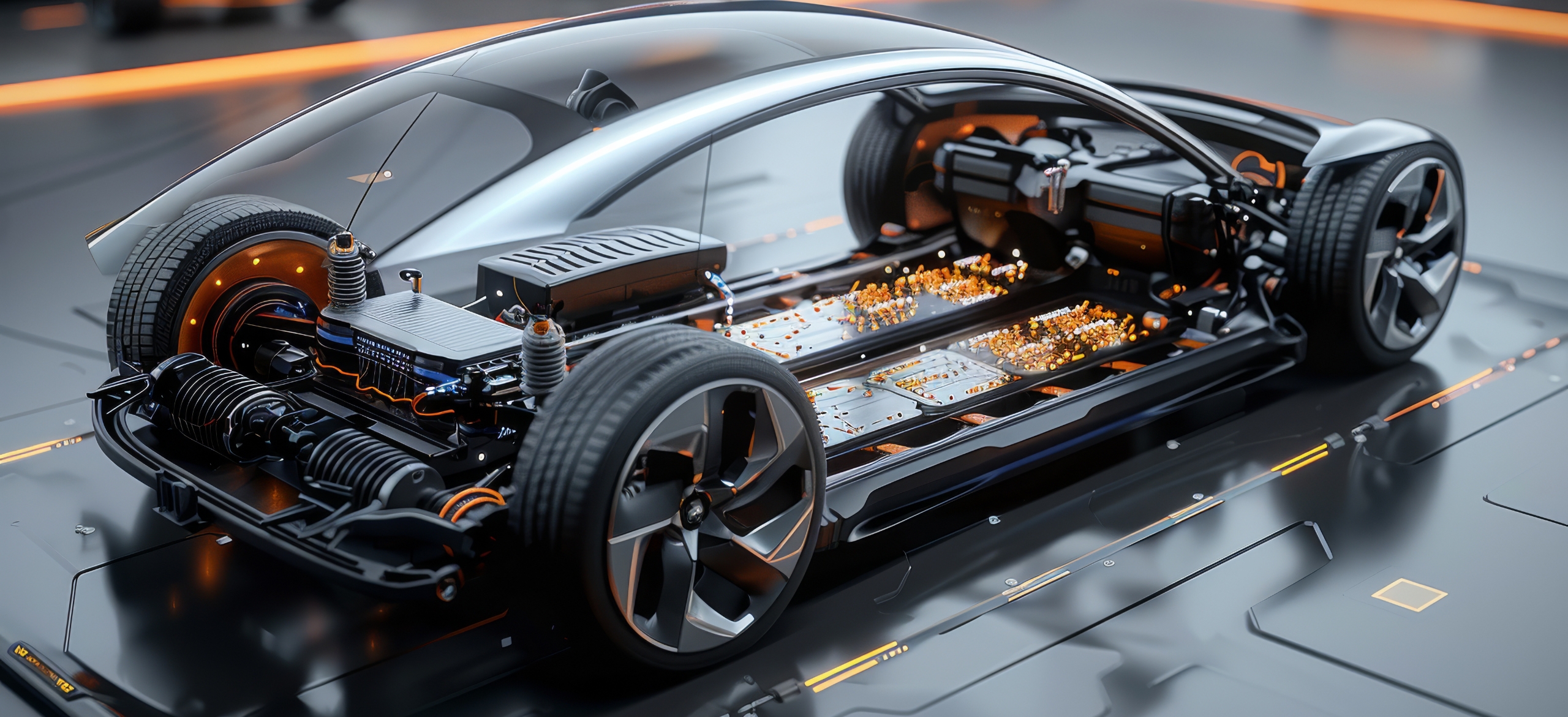

True to our work in the electric vehicle field, we provide EV charging stations for our employees at our headquarters. In the past, our employees supported active composting programs, which helped to divert hundreds of gallons from landfills. In 2019, six percent of our employees drove electric vehicles to work, while 14 percent either walked, biked, or used public transportation. Of course, since then, we have embraced the hybrid workweek with the added bonus of reducing emissions with less commuting.