Telematics is among the most valuable resources you can leverage when it comes to mobile robotics fleet management. Telematic capabilities combine telecommunications technology, operational data, and informatics (i.e., the science of computational systems and data).

With this information, fleet managers can precisely understand mobile robots and their components’ current status. The resulting insights that telematics provides are directly tied to maximizing productivity, operational efficiency, and your return on investment (ROI) when managing a fleet of mobile robots.

What is Telematics?

Telematics broadly refers to the systems that collect and transmit on-board operational data for fleet and equipment assets and the data itself. The fleets may be mobile robots, for cargo transportation, construction machinery, and more. The data collected includes:

-

GPS location

-

Battery health

-

Battery charging efficiency

-

Sensor health and malfunctions

-

Mechanical health and malfunctions

This data provides crucial inputs for artificial intelligence (AI) and machine learning systems that control mobile robots during operation (e.g., navigation, opportunity charging). Personnel responsible for overall fleet management rely on these necessary inputs to identify and prevent issues before they become critical equipment failures.

Telematics data has traditionally been used for maintenance efforts, more accurate staff schedules, and resource planning. Within one vehicle or machine, telematic communications rely on numerous sensors unified through a controller area network (CAN bus). However, USB or wireless data transfers allow telematic information to be aggregated in a database for holistic operations analysis or granular views of individual robots.

Battery and Charge Data – An Example of Telematics

Mobile robots are universally battery-powered. As a result, battery health and charger performance are critical to streamlining operations and fleet management.

Battery and charger telematics data includes:

-

Time spent continuously charging

-

Charging frequency

-

Current and voltage levels

-

Battery temperatures while charging

By monitoring this charge data collected in real-time, fleet managers can:

-

Identify when charging habits are ineffective or damaging battery health, which avoids added costs from repair or service calls

-

Submit warranty claims

-

Optimize charging practices via battery management system (BMS) software

Rod Dayrit, Delta-Q Technologies’ Director of Business Development, recently spoke with LHI magazine on the impact of telematics, lithium batteries, and emerging technologies like smart chargers. Based on data provided by the battery and charger, the charging process can be fine-tuned in real-time to ensure each unit reaches full capacity in the fastest and safest way.

The Benefits of Telematics

Data leads to insights, which facilitate informed planning and decision-making.

Telematics data will provide your mobile robot fleet managers with the best insight into day-to-day and long-term operations. While these use cases still help optimize facility-wide workflows, AI and machine learning systems can also leverage telematics to continually refine their own task fulfillment in real time.

Optimized Facility Workflows

The total distance mobile robots travel within facilities may seem negligible, but it quickly adds up. Consider that—in the US alone—Amazon operates 305 large warehouses (averaging 800,000 square feet) and intends to expand to 355 in 2023 (totaling 319 million square feet).

For a comparative reference to how much distance mobile robots will travel in these facilities, an Amazon employee brochure states that workers will walk “upwards of 12 miles” per shift.

It is important to note that this is not a 1:1 comparison since mobile robot deployment typically results in a collaborative environment rather than worker replacement. Still, it would only take roughly 84 workdays for one mobile robot to cover over 1000 miles at an equivalent pace to the posted employee expectation.

A mobile robot’s route can be analyzed and optimized similar to the way UPS’ AI navigation system, ORION, leveraged GPS and telematics data to reduce their drivers’ travel distance by up to 12 miles per day. On-board AI systems can determine their best immediate path in real-time, while fleet managers and data engineers can identify optimal routes for the entire fleet to follow.

Streamlined Maintenance and Preventing Equipment Failure

In the summer of 2021, it was reported that Amazon had deployed 350,000 mobile robots in their warehouse facilities. Even after distributing them across all large warehouses and its 1,137 fulfillment centers, it is clear that “fleet” accurately describes the number of mobile robots present at each Amazon facility.

Amazon represents a corporation responsible for managing an enormous volume of both facilities and mobile robots. Their average fulfillment center likely deploys (or will soon deploy) tens to hundreds of autonomous mobile robots (AMRs) and automated guided vehicles (AGVs).

Performing regular maintenance on fleets within that range is a significant undertaking—one riddled with massive operational challenges if the approach is reactionary. Without telematics, fleet managers must rely on performing time-consuming manual inspections on each robot individually. As a result, adopting a proactive effort becomes virtually impossible, let alone ensuring robot longevity for maximum ROI.

Instead, telematics enables fleet managers to schedule predictive maintenance, ensure parts availability, and perform upkeep tasks before equipment failures impact daily operations. The maintenance activities are also readily logged for accurate record keeping. Supporting a proactive approach via telematics is simply essential when failures affect the number of available robots or breakdowns occur in inconvenient or disruptive locations on facility floors.

Insightful Scaling and Resource Deployment

How should companies begin their planning stages when leveraging mobile robot deployments to scale operations or expand their number of facilities?

With a holistic analysis of your telematics, data engineers and planning personnel can readily determine how many mobile robots will be needed to:

-

Increase throughput

-

Deploy robots in a new facility

-

Cover the average number of units cycled out of active duty for maintenance

Planning can also better account for what layout provides the most seamless navigation and workflows. For example, one planning recommendation for facilities utilizing mobile robots is to organize warehouse shelving and charging stations within dedicated zones and along unidirectional routes to reduce travel distance and congestion.

Maximizing Mobile Robots’ Efficiency and ROI with Telematics

Without telematics data, it is impossible to truly maximize the operational efficiency and ROI of mobile robots. Between workflow optimization, predictive maintenance scheduling, and future facilities planning, there are too many variables to account for. Extensive analysis is necessary for these aspects of running a warehouse or a facility that leverages mobile robotics.

On a per-unit basis, telematics enables AI systems to optimize:

-

Current task queues

-

Navigation

-

When to charge and at which station

-

Predictive maintenance that helps ensure longevity

And at a holistic level, entire fleet workflows and facility layouts can be determined according to extensive operational and navigation data that the robots accumulate over time.

Want to learn more?

Visit our landing page for more information on the application and technology trends in mobile robotics.

About Delta-Q Technologies

Delta-Q Technologies is charging the future and driving the world’s transition into electric energy! We collaboratively design, test, and manufacture robust battery chargers, that improve the performance of our customer’s electric drive vehicles and industrial machines. As the supplier of choice for Tier 1 OEMs, they use their values, perseverance, and engineering expertise to guide their customers through the electrification process for a sustainable world.

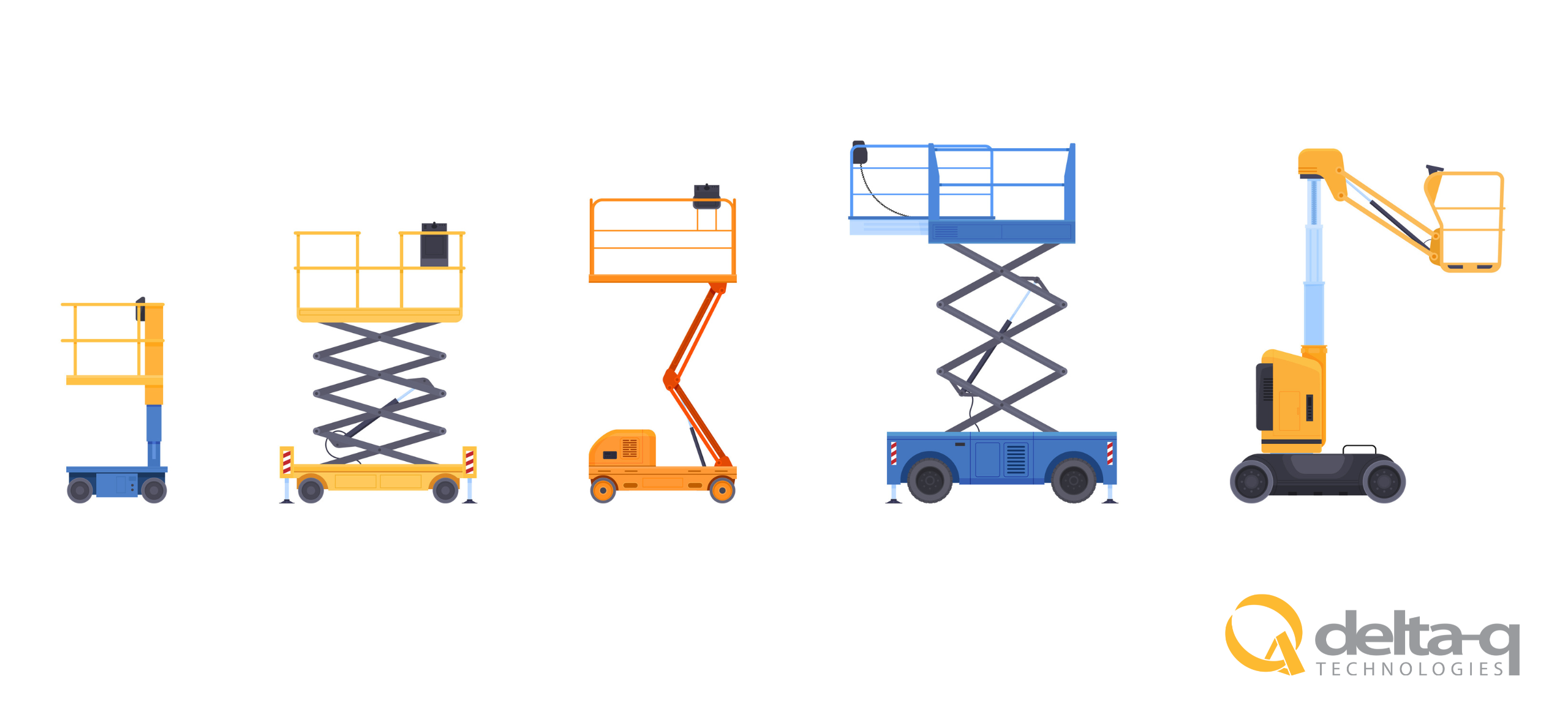

They are part of the ZAPI GROUP of companies and are headquartered in Vancouver, Canada. Delta-Q’s team and distribution span five continents to service industries such as electric golf cars, lift trucks, aerial work platforms, e-mobility, floor care machines, utility/recreational vehicles, and new markets, like outdoor power equipment, marine and construction equipment. For more information, please visit www.delta-q.com or follow company updates on Twitter and LinkedIn.