For industrial OEMs, reliability is just as critical as efficiency.

As electrification expands into off-road and industrial applications, the demand for durable, high-performance on-board chargers has never been greater. This is especially true for compact machinery, where every inch of space must deliver maximum impact.

Whether operating in construction, agriculture, or warehousing logistics, the rigors of modern industrial work zones call for charging solutions that can keep up.

While operating conditions may be tough, with thoughtful design and the right component choice, even the harshest environments need not impede equipment reliability.

Environmental Challenges Facing On-Board Chargers

A growing number of OEMs opt for on-board charging solutions due to their operational versatility. Such chargers enable machinery to recharge from standard wall outlets, reducing the need for costly charging installations and empowering more autonomous operation across varied worksites.

However, these advantages come with design implications.

Unlike their off-board counterparts, on-board chargers move with the machine—exposing them to everything the equipment itself encounters. This could include:

- Rain and moisture

- Dust and debris

- Shock and vibration

- Temperature extremes

For OEMs, this risk of exposure means the charger must not only deliver efficient energy transfer but also do so safely and reliably across demanding applications.

Five Risk Factors—and How OEMs Can Address Them

The above-mentioned challenges are but a sample of the real-world environmental risks facing electrified equipment.

Without the right protection, these stressors could compromise charging performance and risk battery damage—compromising the most expensive component of an electric drivetrain.

Given these dangers, consider five risk factors in closer detail and how OEMs can effectively mitigate them through smart charger selection.

#1. Dust and Water: Ingress Protection Ratings

Industrial settings see frequent exposure to worksite dust and rain. Moisture can cause corrosion or even short out circuitry entirely, whereas dust accumulation may lead to overheating, arcing, or even fire hazards over time.

The answer? OEMs must prioritize chargers with high ingress protection (IP) ratings—specifically IP66 or IP67. These standards ensure complete protection against dust ingress and resistance to water, even up to temporary immersion.

Properly sealed chargers can protect against:

- Air particulate buildup from dusty construction sites

- Chemicals sprayed by agricultural equipment

- Heavy rain and mud in outdoor industrial settings

Look for charging solutions with sealed enclosures and weatherproofed connectors. These design elements ensure dust and water pose no threat to the charger’s operability.

#2. Heat and Cold: Thermal Management Strategies

Chargers naturally generate heat during operation. When paired with high ambient temperatures or confined installation spaces, thermal buildup can impair performance or even trigger safety shutdowns. Conversely, freezing environments increase internal resistance, slowing charge rates and introducing energy losses.

The solution lies in advanced thermal management:

- Aluminum enclosures to facilitate passive heat dissipation

- Wide range of proven operating and storage temperatures

- Built-in over temperature limit protections

Realistically, elevated temperatures pose the greater threat, especially when equipment is in operation and charging solutions are sealed against ingress. Heat cannot escape easily, so it’s essential to select charging systems equipped with strong mechanical cooling, such as variable-speed fans.

#3. Vibration and Shock: Mechanical Reinforcement

Rough terrain, sudden impacts, and continuous vibrations are standard occurrences in industrial settings. However, without an adequately tested charger, such mechanical stress can loosen, crack, or even damage crucial components and connectors.

To address this, a reliable charging solution is essential, built with:

- Enclosures tested for automotive-grade shock and vibration

- Ruggedized, fully sealed casing rated purpose-built for industrial settings

- Standardized mounting points to prevent loose connectors

OEMs must also consider the risk of electrical shock, governed by regulatory standards such as the UL1564 (in the US) and EN 60335-2-29 (in Europe), ensuring proper insulation and electric shock protection is in place.

#4. Electromagnetic Compatibility: Minimizing System Interference

Electromagnetic interference (EMI) and radio frequency interference (RFI) are often overlooked. But in modern charging solutions, densely packed with electronics, unmanaged interference can degrade signal and communication quality across the entire machine.

To minimize interference, OEMs should verify that charging solutions align with international EMI standards, such as:

These certifications confirm that the charger features robust filtering and shielding, reducing the risk of cross-system interference.

#5. Cabling and Connections: A Critical Consideration

Cabling connectors often bear the brunt of environmental stress, from sun exposure and abrasion to repeated operator handling. This makes them the most exposed—and thus most failure-prone—elements to any electrification system.

To ensure these connections contribute to overall durability, consider a charger that features either:

- Integrated architecture – Combines critical components, such as converters and charging interfaces, within a single sealed unit to minimize external wiring and potential failure points.

- Flexible customizations – Alternatively, configurable design layouts, such as a standalone charger option matched to OEM needs, reduce wiring overall without compromising protection.

In either case, collaboration and component choice are crucial.

OEMs require a supplier with the expertise to work with them from the design stage. And they need a charging solution that can meet these stringent needs out of the box.

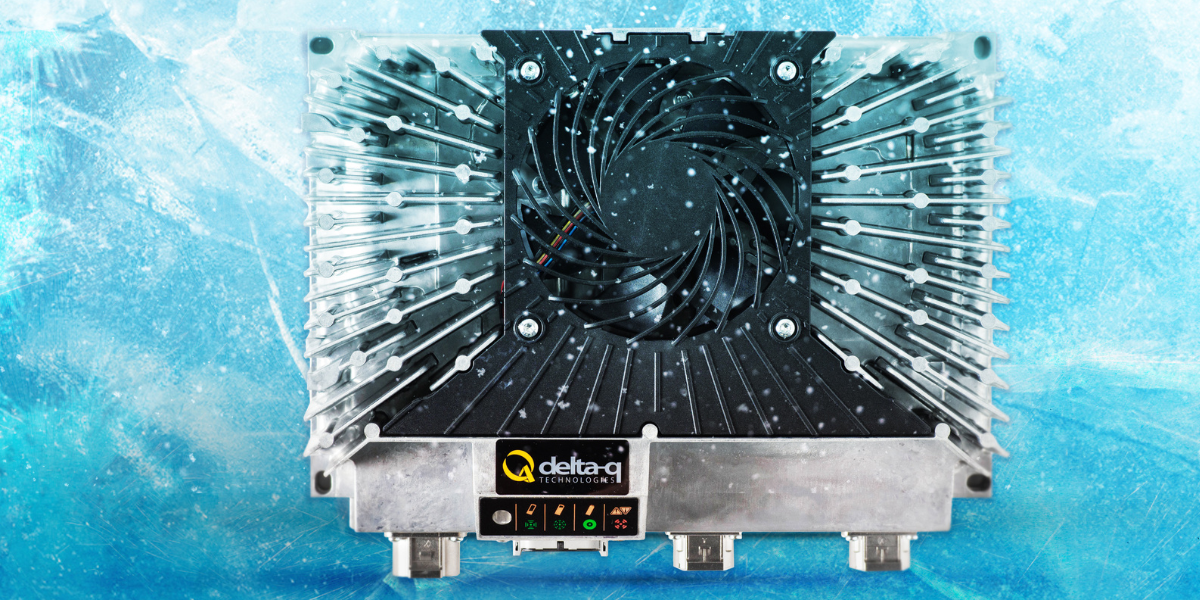

The XV3300: Built for Real-World Reliability

Delta-Q Technologies’ next-generation XV3300 charger exemplifies how these five design considerations can come together in a single, high-performance unit.

Purpose-built for compact non-road machinery, the XV3300 delivers 3.3kW of power in a ruggedized, compact footprint ideal for challenging industrial environments.

This charging solution stands unique in the market with features such as:

- IP66/IP67 rated enclosure for full dust and water protection

- Wide operating temperature range of -40°C to +65°C (-40°F to 149°F)

- Validated for mechanical endurance, including shock, vibration, and thermal fatigue

- Global EMC standards compliance with built-in filtering

- OEM-customizable design with optional DC-DC converter and EV charging interface integration

For OEMs seeking to streamline time-to-market for their next electrification project, the XV3300 offers the durability and design flexibility to meet the most demanding use cases.

Delta-Q Technologies: Powering OEM Designs in Every Environment

Success in electrifying off-road machinery starts with selecting field-tested components—reliability.

Dust, moisture, shock, temperature extremes, and regulatory hurdles remain ongoing challenges. By addressing them with a system-level approach, OEMs ensure longer equipment life and streamlined deployment—efficiency.

With decades of expertise fielding over 4 million chargers and a deep understanding of OEM requirements, Delta-Q Technologies brings unmatched field experience to every solution.

Chargers like the XV3300 prove that OEMs need not choose between reliability and efficiency. The future demands both; and that is exactly what Delta-Q delivers.