As electrification advances beyond highways and into warehouses, many industry experts have been quick to label low-voltages as “complete”—a solved problem.

Yet despite the significant progress, the reality is that demand continues to grow for low-power, low-voltage solutions. For many OEMs, that progress centers around one critical component: the charger.

But whether it’s a floor scrubber or pallet jack, low-voltage electrification offers a practical, cost-effective, and safe path forward for industrial OEMs. And it’s the charger that underpins and enhances every step of the way.

Introduction to Low-Voltages

For global OEMs, the definition of “low-voltage” may vary by region. The International Electrotechnical Commission (IEC) provides a useful baseline, defining low-voltage systems as operating up to 120V DC.

However, this definition comes with several conditions:

- The system must never exceed 120V DC, even under load

- Ripple voltage, the natural fluctuations in current, should not peak above 140V

- Stricter limits may apply in the case of direct user access to live components

Within these boundaries, nominal voltage levels exist at 24V, 48V, 72V, 80V, and 96V. These levels prove ideal for many indoor and light-duty vehicle designs—low enough to avoid demanding safety requirements, but high enough to deliver enough power for the application.

This makes low-voltage platforms well-suited for non-road machinery such as:

- Autonomous mobile robots (AMRs) and automated guided vehicles (AGVs)

- Floor care equipment, like scrubbers and sweepers

- Light-duty material handling vehicles, such as pallet jacks or stackers

- Mobile elevated work platforms (MEWPs)

Rather than the raw power required by heavy-duty or highway-capable EVs, such vehicles need only efficiency, reliability, and simplicity.

And that is exactly where low-voltage systems excel.

Three Advantages of Low-Voltage Platforms

Legacy OEMs pursuing their first electrification project often choose low-voltage platforms for their early designs. Note three reasons why.

#1. Easier Path to Regulatory Compliance

One of the biggest benefits to staying under the 120V threshold? Reduced regulatory complexity. While the exact levels that define low and extra-low voltages vary by region, such systems are universally subjected to fewer electrical safety regulations.

This streamlines the certification process across several fronts:

- Simplified insulation and enclosure requirements

- Fewer steps to securing safety and compliance certifications

- Shorter time-to-market with lower engineering (and legal) overhead

When paired with on-board charging systems pre-certified to meet global standards, OEMs can further accelerate product development, reducing the number of components that require separate validation.

#2. Alignment with Operational Needs

Modern warehouses, retail spaces, and manufacturing floors introduce unique considerations for OEMs and fleet managers. The indoor nature of most worksites demanded electrified platforms to eliminate toxic emissions.

Yet the advantages of low-voltage machinery go beyond that, enabling:

- Improved safety – Lower voltages reduce the risks of electric shock, output overvoltage, and short circuits. This simplifies maintenance and repair tasks while ensuring operator safety.

- Infrastructural compatibility – Low-voltage on-board charging solutions allow OEMs to leverage standard AC wall outlets for recharging, reducing infrastructural overhead and reclaiming floor space.

- Lighter frame – From a mechanical design perspective, low-voltage equipment requires fewer wires, cabling, insulation, and cooling versus higher-voltage packages. This translates to power-dense machine designs capable of delivering maximum power for their size and weight.

These benefits synergize with the other advantages inherent to electrification. Besides cutting CO2 emissions, they reduce operational noise and vibrations, maximizing operator comfort.

#3. Integrated Charging Solutions

An often overlooked advantage lies in the underlying charging infrastructure. Low-power battery chargers present a balanced approach, equipping OEMs to:

- Deploy flexibly across geographies and worksites with a wide voltage support range

- Streamline product development with a matching low-voltage charging output

- Avoid the time and cost of installing dedicated charging stations

- Tap into integrated intelligence with paired battery management systems (BMS)

The right charging solution also improves battery longevity, protecting an OEM’s most costly electrification investment by applying tailored charge profiles. This leads to fewer failures and longer equipment life—key ROI indicators for fleet operations.

The XV3300: Low-Voltage Charging for Industrial OEMs

Electrification isn’t a singular solution; it must be tailored to the application.

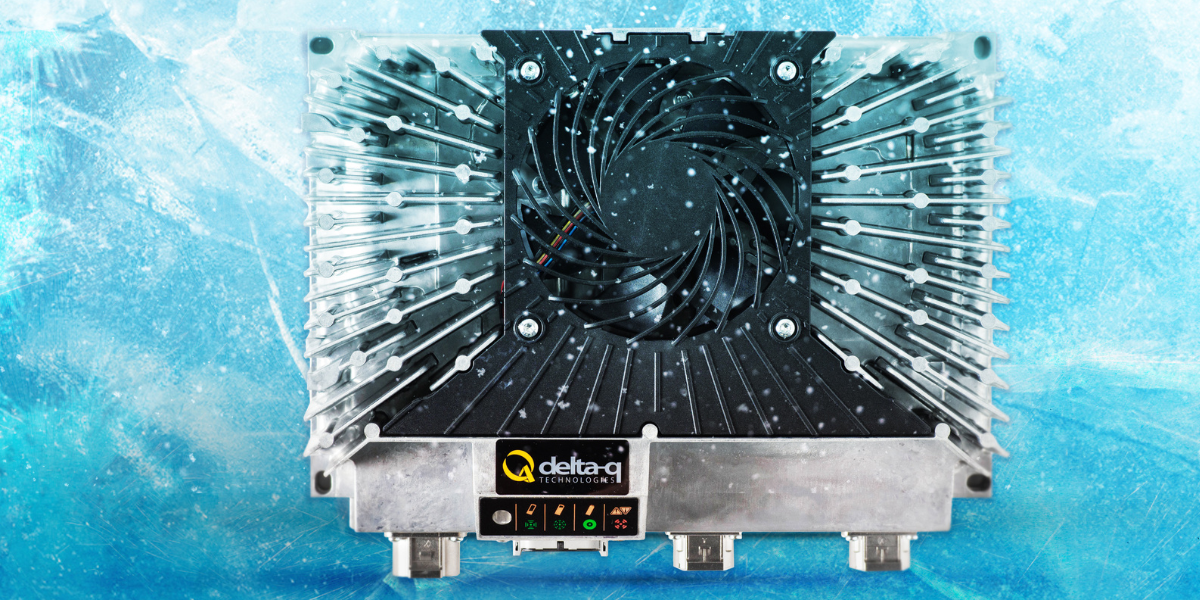

Delta-Q Technologies’ next-generation of industrial charging solutions, the XV3300, empowers OEMs to find that balance in their electrified designs. Capable of charging any nominal 48V, 80V, or 96V battery pack, the XV3300 is an ideal choice for light-duty and indoor applications.

In fact, the XV3300 is engineered to maximize the previously noted benefits of low-voltage equipment, enabling OEMs to:

- Simplify regulatory compliance with a turnkey charging solution, tested to meet the stringent specifications across safety, emissions, efficiency, operational, and other categories. Wide AC input ranges and compliance ensure easy deployment in North America, Europe, Australia, New Zealand, and other territories.

- Align with operational needs via the XV3300’s uniquely “stackable” power output. Up to six of the 3.3 kW models can operate in parallel, delivering a maximum of 19.8 kW of charging power, scalable to OEM requirements. Enhanced safety features, such as a sealed, ruggedized IP66/IP67-rated enclosure, robust thermal management, and enhanced electrical protections further facilitate reliable operations.

- Integrate into overall machine design with CANopen and SAE J1939 protocols, enabling seamless communications with the battery management system (BMS) and vehicle control unit (VCU). The XV3300’s revamped design also features a patented “3-in-1” option, combining a battery charger, DC-DC converter, and EVSE interface within a compact footprint, saving weight, cabling, and cost. Though optional, this customizable package allows for even greater application-specific optimization.

Whether operating as a 3-in-1 solution or standalone charger, integrated into an automated forklift or elevated work platform, the next-generation XV3300 powers future-ready fleets for OEMs across the globe.

Delta-Q Technologies: Low-Power, High Value Charging Solutions

For many applications, low-voltage systems paired with compact, on-board charging solutions deliver the ideal balance of safety, simplicity, and performance. As regulatory landscapes push more OEMs towards electrification, the value of low-voltage platforms will only grow.

Delta-Q Technologies aims to support this escalating demand with on-board chargers such as the XV3300, iteratively designed for real-world OEM applications.

Armed with cutting-edge charging technology and supported by Delta-Q’s 25+ years of electrification expertise, industrial OEMs position themselves to ensure maximum ROI for every vehicle.

Ready to find out how the XV3300 can support your next electrification project? Contact a Delta-Q expert today.