The need for compact non-road mobile machinery (NRMM) continues to surge.

Compact equipment is projected to outpace the greater global market with a compound annual growth rate (CAGR) of 5.1%. Yet as emissions regulations (and operating budgets) tighten, equipment demand stretches beyond what combustion machinery can deliver.

Electrified machinery is emerging as a strong contender in delivering the efficiency, reliability, and sustainability to meet this burgeoning demand head-on. And when designing electrified machinery, tailored charging solutions play a pivotal role in ensuring reliability and driving return on investment (ROI).

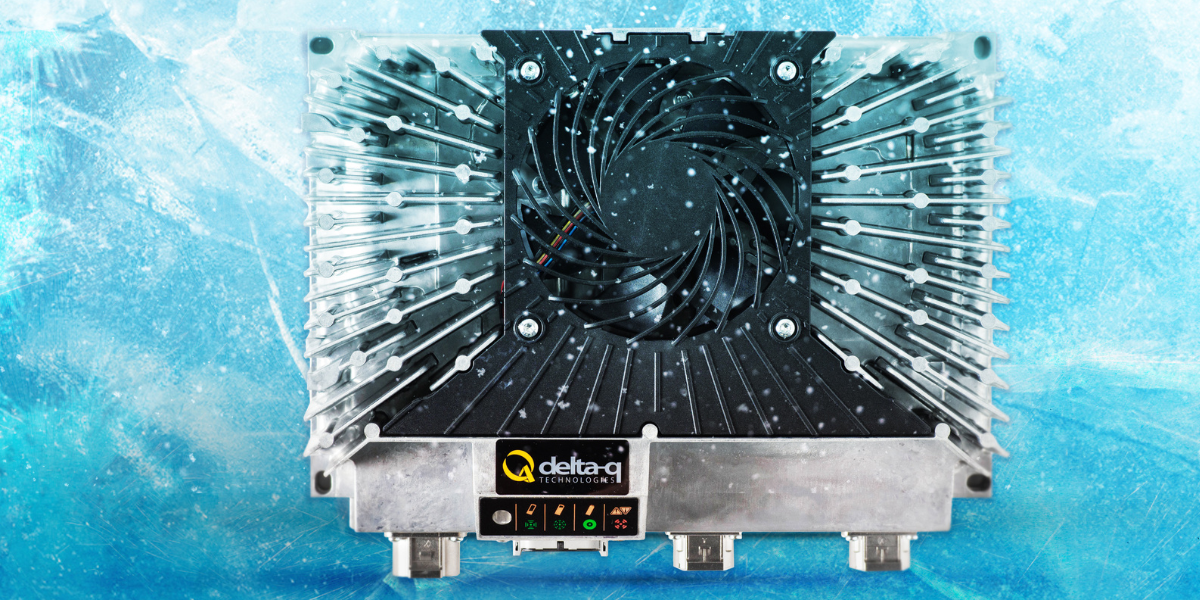

That is where Delta-Q Technologies’ latest charging solution, the XV3300, comes in.

Purpose-built for today’s compact electrified platforms, this next-generation charger delivers the seamless integration, intelligent power management, and modular flexibility needed to meet the demands of tomorrow’s job sites.

Engineered for the Challenges of Off-Road Electrification

With electrification evolving from a theoretical exercise to a very real engineering challenge, OEMs and fleet managers must grapple with new and complex questions:

- Where will the equipment recharge in the field?

- How can design engineers verify system-wide component compatibility?

- What if more power is needed to align charge times with duty cycles?

Sourcing off-the-shelf components often leaves these questions vague and unanswered, especially for light-duty and compact machinery. Systems cobbled together from multiple vendors introduce unforeseen costs, integration hurdles, and performance gaps.

A clear market gap persists—one that demands a purpose-built solution.

A Modular 3-in-1 Charging Solution for Compact Machinery

The XV3300 is an integrated, on-board charging system that addresses these challenges head-on. This next-generation charging solution consolidates three functions into a single, ruggedized unit built for demanding off-road applications.

Those functions include:

- Stackable 3.3kW on-board charger – Compatible with any battery chemistry, from lithium-ion to lead-acid, the charger’s AC/DC power conversion enables charging even via basic residential electrical infrastructure. The system further leverages Delta-Q’s unique “stackable” technology to scale power as needed to the application. Up to six units can charge in parallel, delivering up to 19.8kW of charging power to minimize vehicle downtime and align duty cycles.

- Integrated 500W DC-DC converter – Capable of delivering 12V of secondary power, this built-in converter allows vehicles to run auxiliary systems, such as lights, sensors, and control modules, directly from the battery. Packaging the converter within the XV3300’s rugged IP66/IP67-rated enclosure reduces potential failure points while streamlining compatibility and wiring logistics.

- Public EV charging station interface – The XV3300 comes ready to connect with standard EV charging infrastructure, such as electric vehicle supply equipment (EVSE). Compliance with SAE J1772 (level 1 and 2) and IEC 61851 (mode 2 and 3) standards allows OEMs to seamlessly tap into existing charging infrastructure across North America and Europe.

This all-in-one approach offers several tangible benefits.

For one, it greatly simplifies integration for OEM design engineers. By eliminating separate component boxes, the XV3300’s compact design saves space, weight, cabling, and manufacturing costs.

Such a charging solution also facilitates operational flexibility. With XV3300-equipped machinery capable of charging from virtually any power grid connection, whether public EV charging stations or simple wall outlets, OEMs reduce reliance on costly infrastructure and dedicated charging rooms.

Additionally, integrated designs streamline compatibility and certification checks. The XV3300’s pre-verified components undergo careful engineering to meet global safety and efficiency standards, ensuring it operates as a turnkey solution rather than another design bottleneck.

The benefits extend to a strategic level—aligning OEMs with sustainability mandates while simplifying supply chain logistics. Integrated packages mean fewer SKUs, a shorter design phase, and less effort when integrating chargers into the vehicle’s core features.

These advantages position the XV3300 as an ideal platform for compact machinery electrification.

The XV3300 in the Field: Real-World OEM Applications and Scenarios

While modern electrification trends toward higher voltages, there is still a critical need for charging solutions in low-to-mid-voltage applications. These might include:

- Light-duty construction vehicles

- Material handling equipment

- Mobile elevated work platforms (MEWPs)

- Outdoor power equipment

- Powersports and eMobility

In each case, the charging solution must be fast, intelligent, and capable of withstanding rigorous environments with absolute reliability.

How does the XV3300 measure up? Consider two scenarios:

- MEWPs – Mobile Elevated Work Platforms incorporating the XV3300 benefit from the integrated DC-DC converter. Safety lights, control panels, and sensors run off the main battery, simplifying wiring harnesses and eliminating a potentially hazardous failure point. The integrated EVSE charging interface further allows lifts to utilize existing EV chargers within the facility, streamlining deployment and charging logistics. And with the whole fleet operating on the same charging unit, servicing and maintenance remain straightforward even across different equipment.

- Compact construction equipment – Machinery electrified with the XV3300 benefits from scalable charge power matched to the equipment and duty cycles. For example, an OEM may install six XV3300s in parallel for up to 19.8kW of charging power for an excavator, enabling opportunity charging top-ups during breaks and between shifts. Alternatively, a smaller loader may only need a single unit. Thanks to the system’s modularity, OEMs can leverage a common electric platform and scale the charger configuration up or down to match the usage profile of various models.

Of course, potential applications extend beyond these examples. Any off-highway or specialty vehicle operating on a roughly 48–96 V battery system could benefit from the XV3300.

The XV3300’s Hidden Value Proposition: Delta-Q’s Expertise

For OEMs choosing the XV3300 as their electrification platform, benefits extend beyond the charger’s casing.

Through Delta-Q’s “Charged by Delta-Q” compatibility program, OEMs gain access to a network of validated battery partners. This ensures optimal performance between the charger and battery system, resulting in:

- Maximized battery life

- Improved energy efficiency and reliability

- Lower total cost of ownership (TCO) across the machine lifecycle

For OEMs with specific design constraints, Delta-Q also offers customized variants of the XV3300, including streamlined 2-in-1 or standalone charger configurations to support leaner or more specialized frames.

Delta-Q Technologies: Driving Compact Machine Electrification with the XV3300

The need for compact, electrified NRMM continues to surge—and with it, the need for advanced charging solutions.

While the XV3300 is not a new market offering, its latest generation reflects years of refinement. Driven by customer feedback and engineered for the evolving demands of compact electrified systems, it delivers enhanced integration capabilities, improved stackability, and greater customizability across diverse OEM applications.

With 25 years of electrification expertise to back it, Delta-Q Technologies leads the charge towards a sustainable future, one iterative design at a time.