One Charger, Various Technologies

Wide output voltage to support all lead-acid (WET, GEL, AGM) and lithium chemistries (LCO, NCA, NMC, LMO, LFP, LTO) .

Charging Flexibility

Capable of storing up to 25 lead-acid or lithium charge algorithms, switch to lithium charging without switching chargers to future proof machine design.

CISPR14 Residential Emissions and Immunity

Compliant to CISPR 14 European cleaning machines’ emissions standards for installation on residential power circuits.

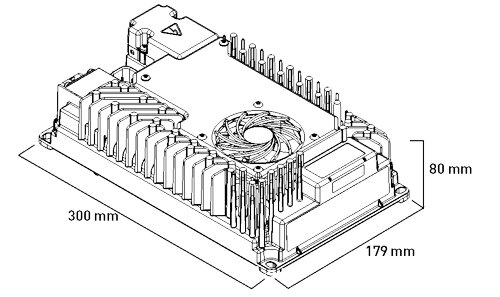

On- and Off-Board Installation

Nulla lobortis enim eget diam aliquam sollicitudin. Mauris facilisis libero sit amet posuere vehicula.

Mounting Flexibility

Stack up to six RC Series chargers, either on-board, off-board, or a combination, to allow for easy integration in compact vehicles and to provide faster charge time for high power options.

Real-Time Charge Data

Extract real-time data including charger status, charge history, and fault and error logs for faster troubleshooting using standard CANOpen and SAE J1939 protocols.