When designing power equipment, machines, and vehicles, product designers must find the smallest, lightest, and cheapest components. The power source is often the bottleneck for size, weight and cost, as well as for run time and reliability. There are many alternatives, but each one comes with its own drawbacks.

Fossil-fueled engines, for instance, may provide high-power density and quick refueling, but its maintenance cost and environmental impacts make it unacceptable to modern users. Electric motors solve many of these issues, but are weighed down by large lead acid batteries and extension cords. The most ideal solution would be cordless, zero-emission, light, powerful and refuellable.

Is there a solution like this on the market? Yes, lithium-ion batteries.

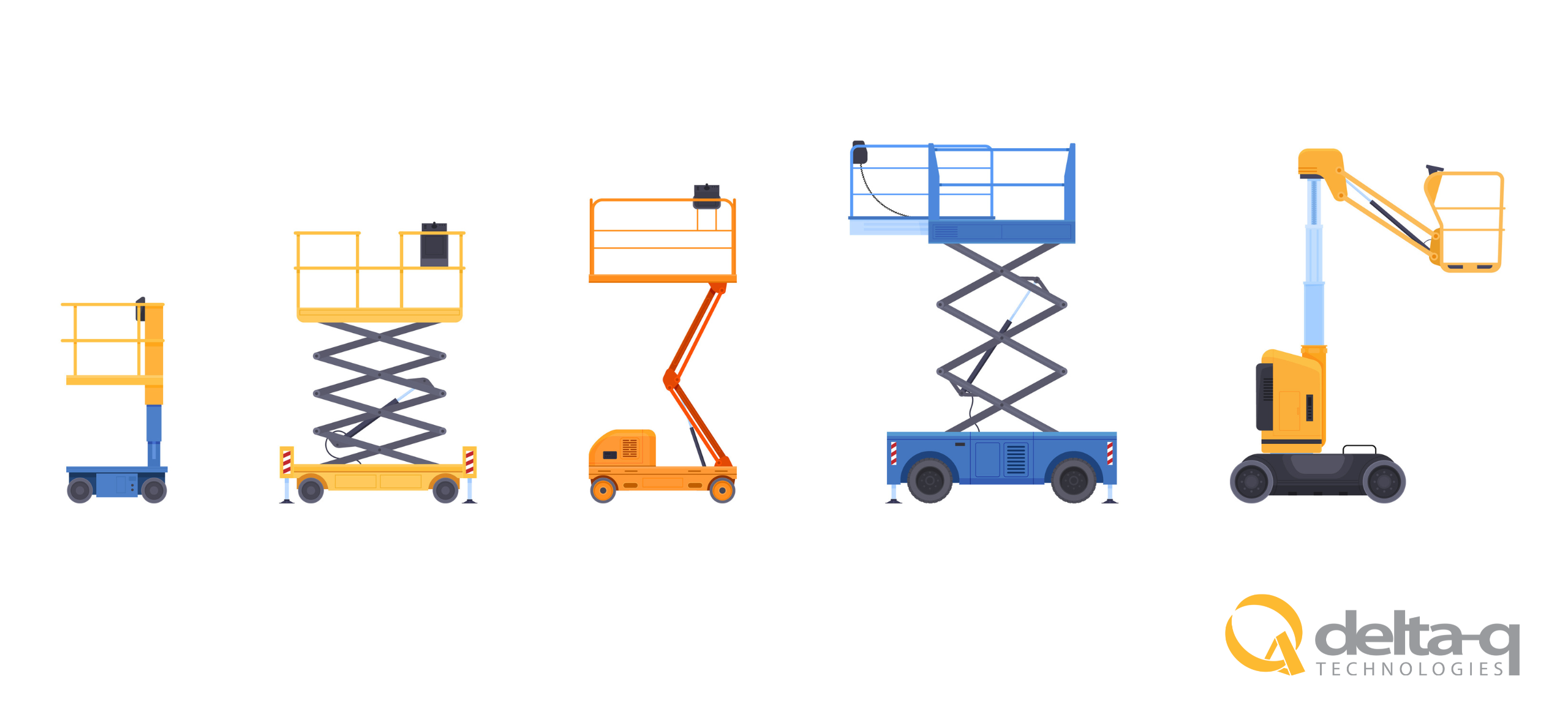

Over the past three decades, lithium-ion batteries have conquered cameras, laptops, and power tools. As lithium-ion prices continue to drop, the solution is poised to take over other markets including electric drive vehicles, lawn mowers, golf carts, and forklifts. Many original equipment manufacturers (OEMs) and distributors are looking to lithium-ion batteries as a significant and disruptive alternative to traditional lead acid batteries. But, to determine if lithium is the right solution for your application, you must have a thorough understanding of lithium-ion batteries and their integration with BMS, and charging solutions.

In this article, Making the switch to lithium-ion: is it right for your product?, featured on Electronics & Products Technology, Chris Botting, manager of research at Delta-Q Technologies, dives into what lithium-ion is, it’s benefits, and challenges of converting, to help you assess if switching to lithium-ion batteries is right for your application.

Read the full article on Electronic Products & Technology’s website.