When developing our charging solutions, we work with battery manufacturers and OEM engineers to determine performance metrics and embed them in a charge algorithm or charge profile—the set of instructions that guide the charger in returning energy to the batteries.

We develop, iteratively test and validate our charge algorithms in close collaboration with the battery manufacturer and OEM engineers. Delta-Q has commercialized more than 250 charge algorithms for leading lead-acid and lithium battery brands and chemistries.

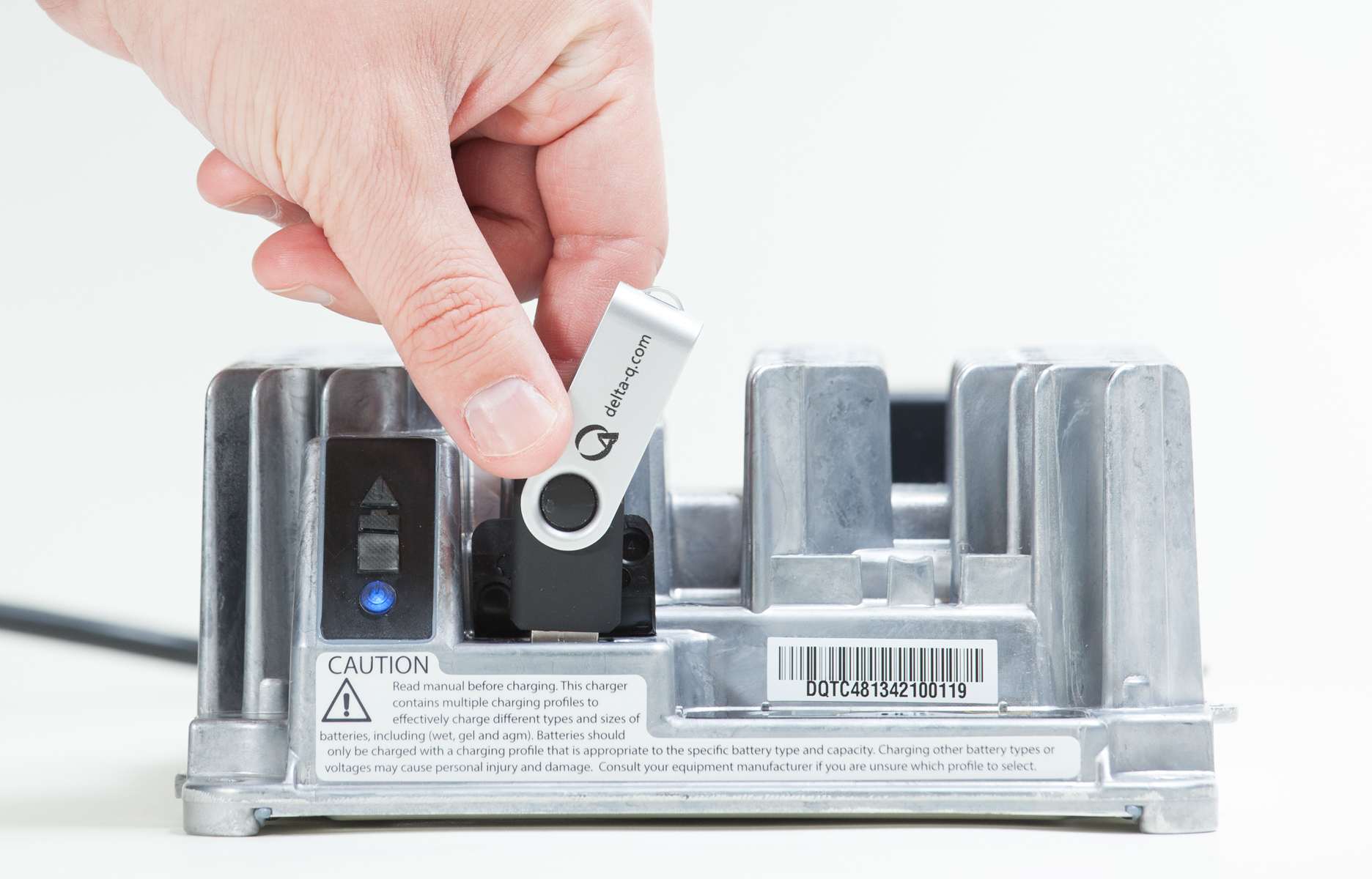

Delta-Q’s charger software undergoes a rigorous software development process. Our team begins by working with the customer to identify design requirements. During the software development process, we use a combination of controls to test every unit. This process helps our team identify and mitigate any software bugs, hazards and other defects that could cause an downtime in the field.

Delta-Q’s software team has over 60 years of CAN programming and customization experience. Our team works directly with OEMs to understand their product requirements and can help fit the charger into the communications and software systems of their battery-powered equipment.

We offer the two leading CAN bus communication protocols used by OEMs: CANOpen and SAE J1939. Based on the vehicle design requirements, OEMs can select or customize the CAN messaging from a comprehensive list of standard messages.

Looking for more information? Find spec sheets, white papers and case studies in our resources section.

Looking for a battery charging solution? Delta-Q develops lead-acid and lithium battery charging solutions with your needs in mind so that you can build an electric drive product with better flexibility and longevity.