Delta-Q embodies a manufacturing philosophy of Continuous Improvement based on setting standards aimed at eliminating waste through the participation of all employees. We partner with Flex (formerly Flextronics), a leading contract manufacturer, and their High-Reliability Products division is responsible for manufacturing our products to automotive quality levels. Our shared approach to LEAN manufacturing methodology eliminates non-value-added activities and focuses on continuous improvement, thereby allowing us to offer premium, high-quality products at competitive price points. Our experienced operations team constantly measures logistics performance and is transparent with global supply chain challenges with our customers. We also have a dedicated OEM support services team that quickly responds and works in the field.

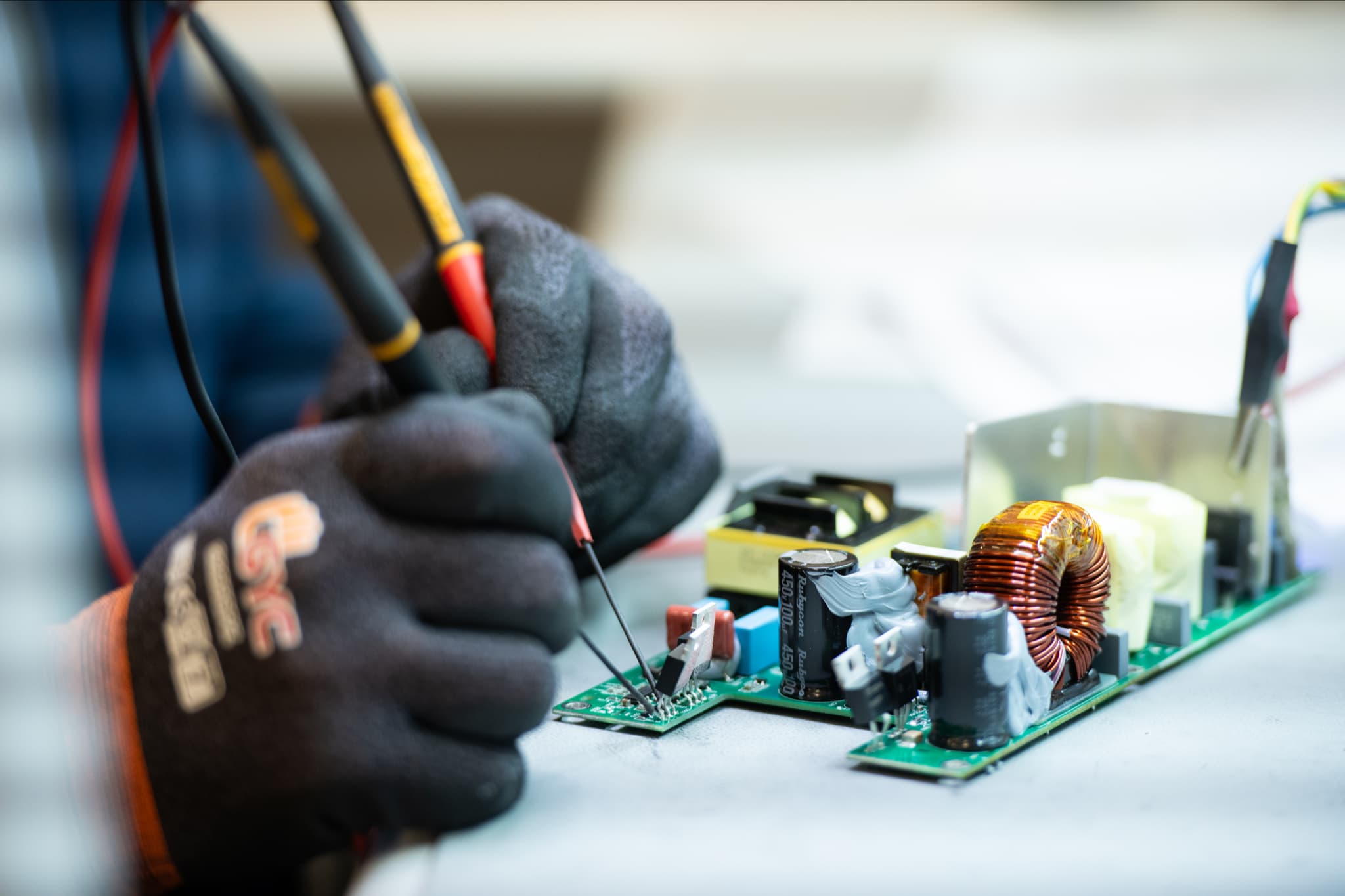

Operations and technical support continues post-delivery through our robust RMA process. The attention to detail in our designs carries through to all returned product scenarios. We keep an open line of communication with our customers to absorb specific product or usage questions and concerns. Defective product percentages are well below industry standards, but we take every small occurrence seriously. Our RMA warranty process team receives returned products at our headquarters for complete analysis. The goal for the analysis is to identify any defects or misuse and put together an actionable prevention plan to mitigate a similar issue in future.

Our multi-disciplinary operations team offers customer support at every level. Whether they are on a production line or tracking shipment progress, our operations team offers full transparency to customers. At any point in time, an OEM should have a firm grasp on the status of their project based on Delta-Q’s proactive communication. We favor proactivity over reactivity but we have the expertise to manage all scenarios.

We subscribe to the principals of lean manufacturing. Each piece of our manufacturing process has to “earn its spot.” All systems employed must contribute to the overall manufacturing efficiency. Our commitment to optimizing efficiency is not a stagnant metric, but an active goal for each member of our operations team. Our partnership with Flex opened up further efficiencies in the form of increased distribution and production line capacity.

Looking for more information? Find spec sheets, white papers and case studies in our resources section.

Looking for a battery charging solution? Delta-Q develops lead-acid and lithium battery charging solutions with your needs in mind so that you can build an electric drive product with better flexibility and longevity.