Internal combustion engines (ICEs)—gas or diesel—represent one of today’s most significant environmental threats. From petroleum-based fuel extraction and refinement to consumption in vehicles and other applications, ICEs produce greenhouse gas (GHG) and particle emissions that disrupt nature’s lifecycles and systems and harm all organisms.

Different ICE models, better fuel refinement, emissions reduction technologies, and other innovations have reduced ICE pollution. But OEMs and other stakeholders have yet to determine a consensus on which paths to pursue toward sustainability.

And with the industry constantly in flux from concurrent advancements, questions like “Is diesel or gas better for the environment?” continue to pop up—with the answers sometimes changing based on differing assessment methods or the latest innovations. So, below, we’ll examine internal combustion engines, innovations, and their environmental impact compared to carbon-neutral solutions like electric drive.

Internal Combustion Engines (ICEs) and How They Impact the Environment

An ICE refers to a heat engine that generates power by consuming fuel via combustion. Most commonly, ICEs consume carbon-based fossil fuels—gas or diesel—that emit significant pollutants (e.g., carbon dioxide) into the environment. And over the last 200+ years, measurements of atmospheric carbon dioxide have risen from 278 parts per million (ppm) to over 417 ppm—a 50% increase.

With enough emissions, the environment’s natural processes for sequestering carbon—such as photosynthesis—cannot keep pace. The excess atmospheric carbon traps heat, leading to climate shifts and general temperature increases that impact various other environmental cycles. Moreover, hydrocarbon fuels (which include fossil fuels) can contaminate soil and water, negatively impacting growth rates, health, and biological processes for all organisms.

What Pollutants Do Internal Combustion Engines Produce?

The pollution caused by ICEs primarily comprises three outputs:

-

Greenhouse gasses (GHGs) – GHGs contribute to climate change and global warming by absorbing energy and trapping heat within the Earth’s atmosphere. ICEs emit all three of the most prevalent GHGs:

- Carbon dioxide (CO2)

- Methane (CH4)

- Nitrous oxide (N2O)

-

Hazardous gasses – Hazardous gasses are toxic gasses that can cause severe physiological effects when inhaled. These are comprised of the following:

- Carbon monoxide (CO), an odorless, tasteless, and colorless gas capable of killing those who inhale it.

- Nitrogen oxides (NOx), which include nitrogen oxide and nitrogen dioxide. Nitrogen oxides can have serious effects on the environment and the respiratory systems of both humans and animals.

- Particulate matter (PM) – Particulate matter—or “particle pollution”—refers to tiny, airborne solid or liquid matter like soot and dust. ICEs (and diesel engines especially) emit significant amounts of PM that pose severe environmental (e.g., ground-level ozone) and health risks (e.g., cancer).

Is Gas or Diesel Better for the Environment?

Determining whether gas or diesel ICEs are better for the environment depends on the comparison used. Per most entities—such as the International Council on Clean Transportation (ICCT) and the US Energy Information Administration (EIA)—and researchers, diesel fuel environmental issues exceed those of gas.

For example, an ICCT comparison of gas and diesel engines found the latter produced more CO2 across all laboratory and real-world applications. However, the differences between fuels become less clear after accounting for other factors:

- Diesel typically consumes less fuel by volume for the same applications.

- As a paper published by researchers at the Eindhoven University of Technology asserts, fully accounting for ICE emissions requires adding 24% to diesel and 30% to gas engines for fuel production. Applying those modifiers to the ICCT study would reverse the outcome in many of its tests.

The Effects of Diesel Exhaust on the Environment

Diesel engines generally produce more emissions pollution because they do not always burn all the fuel they consume. This “incomplete combustion” becomes more likely if there is not enough oxygen present (or sufficient temperature). The leftover fuel is forced out of the combustion chamber during the four-stroke cycle, releasing more hydrocarbons.

Increased emissions of PM and hydrocarbons in the atmosphere can have detrimental effects on the environment and human health. This includes reduced visibility (i.e., haze), damage to crops, trees and other vegetation, and increased cancer risk.

ICE Solutions for Sustainability

For many engine manufacturers and OEMs, their sustainability strategies continue to hinge on reducing ICEs’ environmental impacts. Even when pursuing other solutions (e.g., electrification, hybrids, alternative fuels) simultaneously, these efforts remain significant given the traditional market dominance of ICE vehicles, machines, and equipment.

Gas and diesel emissions reduction technologies achieving more environmentally friendly operation include:

- New combustion systems (e.g., Kubota’s TVCR) and improved electronic control

- Turbocharging

- Cylinder and piston design

- Expanded exhaust gas recirculation (EGR) tolerance

- NOx after treatments (e.g., diesel exhaust fluid (DEF))

The benefits of these strategies and their broader adoption remain to be seen, but they’re undoubtedly improvements over past performance.

Multifaceted Solutions to Climate Change

Original equipment manufacturers (OEMs) seeking to reduce the environmental impact of their products and comply with increasingly strict regulations will need to determine which solutions to invest in for the future. However, their current strategic challenge results from a global innovation and infrastructure gap.

For example, the advancement in electric drive continually proves to be among the most viable solutions to achieving zero-emission operation. Yet concerns over charging infrastructure availability have restrained electric drive innovation or adoption for some applications. Similarly, fueling infrastructure and OEMs’ generally nascent investments are currently hampering hydrogen fuel cell technology’s viability.

Accordingly, the industry remains in flux, with manufacturers’ strategies simultaneously including:

- Developing hybrid options to leverage ICE and electric motor benefits

- Researching new diesel innovations and alternative fuels (e.g., renewable diesel (HVO))

- Testing the market viability of hydrogen fuel cells

Electrification for Better Sustainability

Ultimately, ICE innovation will not provide the most sustainable solution overall because fossil fuel consumption will always struggle to achieve zero emission operations compared to options like electric drive. However, ICE improvements remain necessary for now. Despite substantial innovations and investment, some alternatives needed to address climate change may not be viable to the market’s majority until closer to 2030 or beyond (e.g. hydrogen fuel cells).

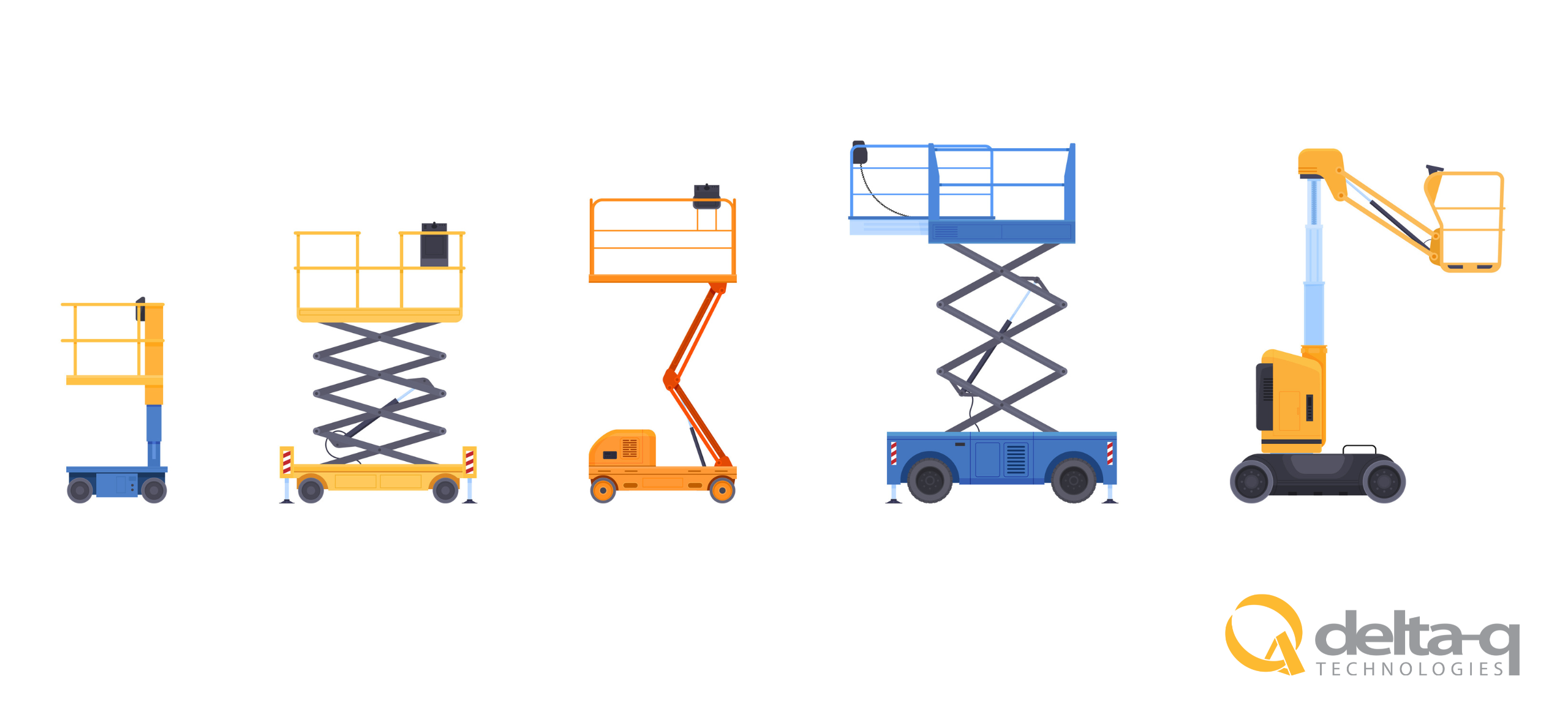

Of the possible solutions, electrification is one of the most revolutionary (and currently accessible). Electric drive completely eliminates operational emissions, and emissions related to electricity generation can also be eliminated via wind, solar, and other methods. Crucially, battery and related technologies continue to advance (e.g., improved chemistries and charger designs), accelerating electrification.

How Can Delta-Q Help?

Because many OEMs still need to familiarize themselves with electric drive technology and alternative fuels, the ongoing transition away from ICEs will require collaboration with experts in motors, batteries, and charging capabilities. For example, OEMs will need to determine the trade-offs regarding basic specifications, reliability, size, cost, and system integrations for battery chargers.

These partners will be instrumental in determining performance needs, engineering new systems and components, optimizing manufacturing, and sourcing competitively priced materials. And Delta-Q Technologies provides that expertise as a leader in charging innovations needed for OEMs to pursue electric and hybrid drive solutions.