Protecting On-Board Chargers Against Operating Environments

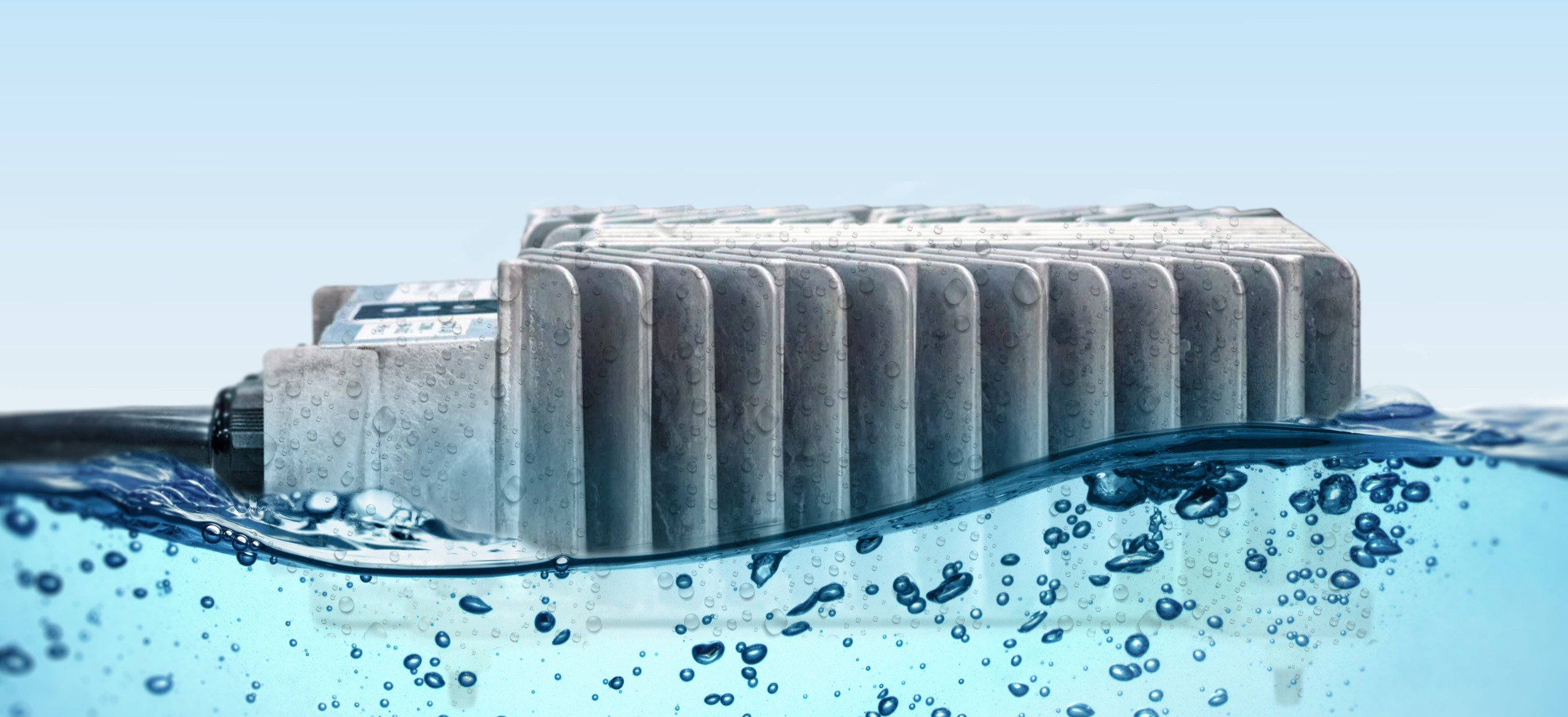

Operating environments for mobile machinery often subject on-board battery chargers to demanding conditions. Outdoor and wet environments will risk introducing dirt and liquids into the units—potentially damaging circuit boards, connectors, and other components—without proper sealing and protection in place.

Original equipment manufacturers (OEMs) need to know that the on-board chargers they outfit machines and equipment with are rated for a given product’s expected environments. This is tested and verified via the IP rating system. Additionally, OEMs must consider charger mounting locations during product design phases to determine whether additional protection is warranted.

IP Ratings Overview

The International Electrotechnical Commission (IEC) developed IEC 60529 as the industry standard for testing and rating electrical devices. Devices receive an official IP rating depending on their ability to withstand testing conditions that subject them to dirt and water.

IP ratings are displayed as “IPXX”—where each ‘X’ refers to the level of protection against solid-particle and liquid ingress, respectively. The higher the number, the better the device’s protection (although sealing against submergence and sprays may involve separate tests).

Solid Particle IP Ratings

The IP rating for an electric device’s sealing against solid particles ranges from 0 to 6:

- IP0X – The device doesn’t offer any sealing or protection against solid particles.

- IP1X – No ingress of solid objects 50mm Ø (diameter) or larger.

- IP2X – No ingress of solid objects 12.5mm Ø or larger.

- IP3X – No ingress of solid objects 2.5mm Ø or larger.

- IP4X – No ingress of solid objects 1mm Ø or larger.

- IP5X – The device protects against the ingress of some dust.

- IP6X – The device is considered “dust-tight.”

Liquid IP Ratings

The IP rating for an electric device’s sealing against liquids ranges from 0 to 6 for liquid sprays and jets (from any direction):

- IPX0 – The device doesn’t offer any sealing or protection against liquids.

- IPX1 – Vertically falling drops will not harm the device.

- IPX2 – Vertically falling drops will not harm the device even if the enclosure is tilted 15o.

- IPX3 – Water sprays (up to an angle of 60o) will not harm the device.

- IPX4 – Water splashes against the enclosure will not harm the device.

- IPX5 – Water jets directed against the enclosure will not harm the device.

- IPX6 – Powerful water jets directed against the enclosure will not harm the device.

The IP ratings for a device’s protection against submergence or more extreme jets ranges from 7 to 9:

- IPX7 – Temporary submergence in water up to one meter deep for 30 minutes will not harm the device.

- IPX7 testing depends on standard conditions for factors like pressure, temperature, salinity, presence of chemicals, and other factors.

- IPX8 – Prolonged submergence in water deeper than one meter will not harm the device (under manufacturer-specified conditions).

- Manufacturers must specify normal operating environments and conditions to ensure the test results are relevant; the test will mimic these conditions.

- Some water ingress may occur, but not to the extent that it harms the device or its components.

- IPX9 – High-pressure and high-temperature water jets directed against the enclosure will not harm the device.

Common Environmental Considerations for Mobile Machinery and On-Board Chargers

Mobile machinery will likely be exposed to environmental conditions capable of affecting performance and reliability regardless of application.

Even after earning an IP rating that meets standard operating environments, these conditions must be accounted for during OEMs’ product design phase to ensure they protect on-board chargers and can adjust mounting configurations and the placement of other systems as needed.

Direct Ground or Road Sprays

Even when stationary or traveling at lower speeds, mobile machinery and on-board systems, like chargers, may be subjected to sprays (e.g., dirt, puddles). Dirt and mud sprays risk the ingress of finer solid particles that can interfere with various components (e.g., circuit boards, a cooling fan’s rotation), and gravel or rocks risk impact damage.

On-board charger protection against ground sprays is especially important for outdoor applications. This likely involves shielding of some kind—either via dedicated parts or mounting configurations placing chargers so ground sprays can’t reach them. Aside from the charger itself, related systems and components may also require protection—such as plastic fans used for thermal regulation.

However, it’s also important to consider how shielding can affect operation and maintenance:

- Thermal regulation issues – If the shielding is too tight to the charger, the device will struggle to shed heat.

- Access issues – If the charger or shielding is mounted in a way that makes access difficult, maintenance may increase downtime or service costs.

Liquids

Depending on a mobile machine’s standard application, liquids may be a standard environmental factor. Machines operated or stored outdoors will be subjected to precipitation, splashing, and humidity, and some indoor machines—like floor scrubbers—will regularly come into contact with water or chemicals.

For these applications, components connected to or integrated with chargers (e.g., electrical connections, cooling fans) will also require protection to ensure they remain undamaged and workers avoid safety risks.

For example, the connectors for Delta-Q Technologies’ XV3300 charging system are rated as waterproof when mated.

Corrosive Substances

When mobile machines operate in certain conditions, they may be subjected to corrosive substances that can damage on-board chargers and their components. These substances may be present regardless of whether the machine is used and stored in an outdoor or indoor environment.

For example, golf carts and farm equipment likely come into contact with fertilizers, and lift trucks operating near ocean ports will be subjected to salt water (directly or in the air). Indoor usage may involve transporting solvents that could spill (e.g., material handling), or the machine might store and use chemicals (e.g., floor cleaning).And any machinery powered by lead-acid batteries may contend with battery acid.

Ultraviolet Light

Ultraviolet (UV) light shouldn’t pose a significant risk to on-board chargers in most circumstances. However, prolonged or excessive repeat exposure could cause labels to fade and (plastic) enclosures to weaken.

Fading labels shouldn’t affect charger health or service life, but operators, fleet managers, or technicians may need to find information such as product or serial numbers when performing maintenance and ordering replacement parts.

Minimum IP Ratings for On-Board Chargers

Given these operating environment conditions, most on-board chargers for mobile machinery should achieve an IP66 rating at a minimum to ensure dust or powerful water jets will not harm the device. This provides sufficient “catch-all” protection for most scenarios.

The necessity of additional liquid ingress protection depends on the mobile machine’s application.

The Importance of On-Board Charger Mounting Locations

As alluded to above, mounting configurations that place on-board chargers behind other systems or parts can effectively create a shield to improve protections against ingress. For example, a charger that achieves an IP66 rating may effectively be protected against high-pressure, high-temperature jets if it’s placed in a location where those jets cannot reach it.

Delta-Q: Rugged On-Board Chargers for Optimal Performance and Long Service Lives

Regardless of a mobile machine’s application, on-board chargers require protection against environmental conditions—whether fine solid particles, small rocks, mud, or liquids. It’s simply the reality of putting those machines to work.

OEMs can ensure satisfied customers, longer charger service lives, and fewer warranty claims by partnering with an expert like Delta-Q Technologies that knows how to design and test on-board chargers. We collaborate closely with our partners—particularly during design phases—to help OEMs determine the optimal mounting locations and configuration for each charger.

Sources:

IEC. IP ratings. https://www.iec.ch/ip-ratings