Battery Charger System Integration

Battery charger system integration remains one of the most critical decisions for OEMs, particularly those starting to explore electric drive options. The charger must seamlessly integrate both physically (i.e., with other systems and components) on non-road mobile machinery (NRMM) and electrically (i.e., provide appropriate power).

System integration considerations primarily revolve around the charger’s location, power output requirements, and associated trade-offs. We’ll examine these below.

Charger Location and Considerations

One of the first decisions OEMs must make for electric machinery is whether to mount the device on-board, provide it separately for off-board use, or combine both options in a hybrid system. And this decision is impacted substantially by the machine’s application, as each location provides trade-offs to evaluate based on standard operations and work environments.

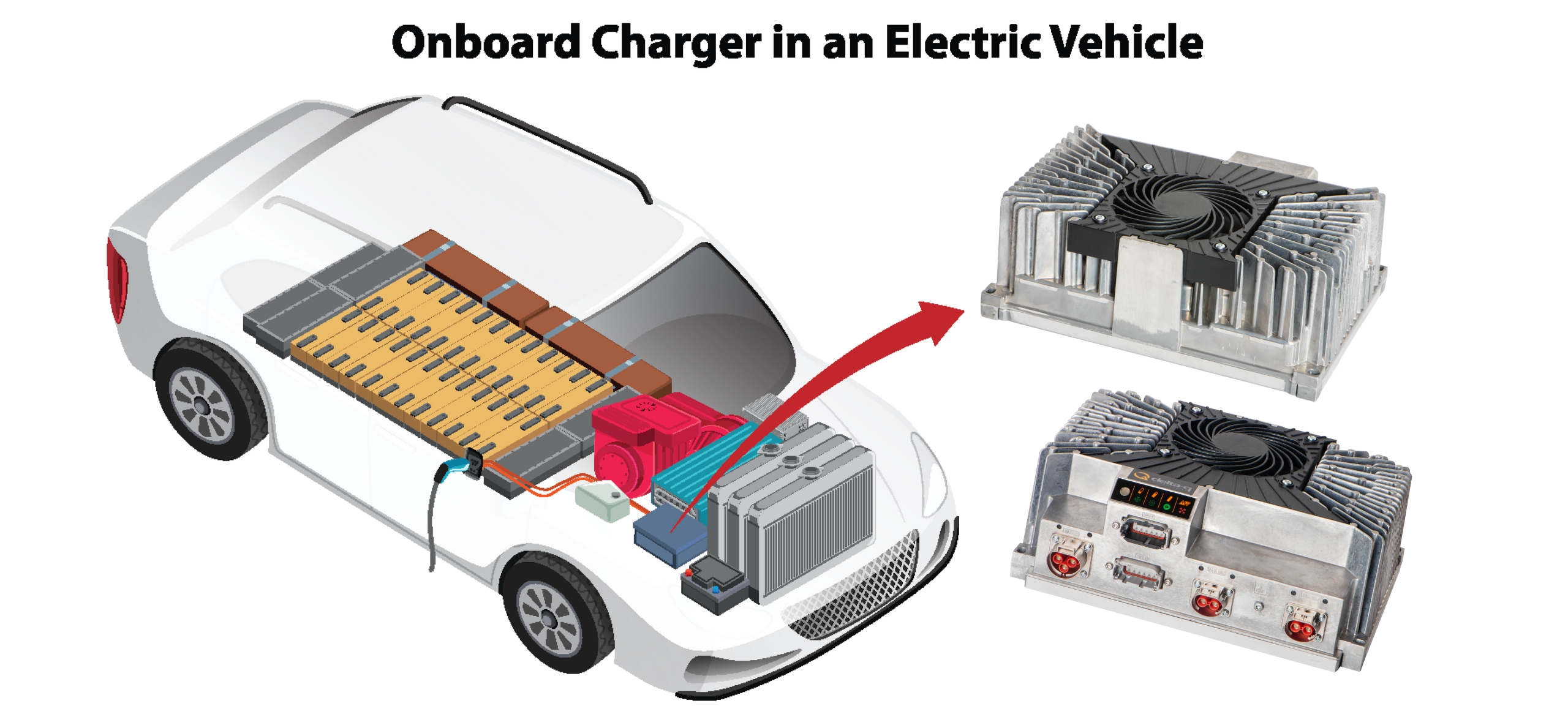

On-Board

On-board chargers often provide the most utility and convenience simply by enabling opportunity charging—or charging from any available power source during breaks or other downtime. Without having to return to a central charging facility, operators can continue using the machines for longer and accomplish more.

Opportunity charging generally benefits all applications, but it might be crucial for some. For example, floor cleaning machines used to scrub massive surface areas would lose substantial time to traveling in addition to charging. And without requiring separate devices and cables, fleet managers can minimize wear and tear or lost units. This is especially impactful for applications where NRMM may be transported between job sites (e.g., construction, rentals).

However, on-board chargers present OEMs with design and engineering challenges related to:

- Available space and charger size – If machine designs must be compact, available space is already at a premium. And outfitting machines with smaller chargers reduces their power output and extends charging times.

- Charger weight – Heavy chargers require more battery power to move the machine, more robust structural support for mounting, and may cause issues for the work environment. For example, agricultural machinery that’s too heavy risks over-compacting soil.

- Environmental considerations and durability – On-board chargers must be designed to withstand the machine’s normal and severe-duty work environments. This can be particularly challenging when those include:

- Liquids and particle sprays

- Extreme temperatures or fluctuations

- Shock, vibration, and other mechanical stresses

Off-Board

Off-board chargers don’t need to contend with the size, weight, or durability concerns that on-board chargers have. However, as standalone units, they:

- May need to pass more stringent design, testing, and certification requirements

- Require all machines to return to central charging facilities whenever on low power or at the end of the day

- Necessitate additional or more sophisticated connections to support data transfer (i.e., telematics)

Additionally, central charging locations must be kept clean (e.g., liquids, chemicals) to limit performance and worker safety risks. And off-board chargers may present an injury risk if stored on shelving or mounted overhead (e.g., caught cables pulling the charger down).

Ultimately, the biggest benefit to off-board charging is that—without any size or weight constraints—OEMs can provide larger devices to deliver more power to the battery and charge it faster.

Hybrid

Hybrid charging systems can function one of two ways:

- The machine provides both on-board and off-board chargers, with the off-board charger used to situationally enable faster opportunity charging. Important considerations include available storage, additional weight, and adequate sealing and protection for both units.

- The machine’s on-board charger is removable, enabling a second battery to charge during operation. Important considerations include removal and reconnection ease, adequate sealing and protection, and storage for the second battery.

Power Requirements

NRMM generally requires a larger battery pack and greater power output capabilities (between 3 and 10 kW) to power the machines. Therefore, they also require larger and more powerful chargers, as evidenced by a simple equation:

Watts (i.e., charger output) x hours (i.e., charging time) = Watt-hours (i.e., battery capacity).

Charging time should generally maintain “overnight” (i.e., 8-12 hours) as a maximum duration, which means charger output power must increase to support larger batteries. However, this can present additional considerations and trade-offs—particularly for on-board chargers.

Connectors

Greater charging power requirements may limit opportunity charging, as residential outlets (i.e., 110-120 V in North America and 220-240 V in Europe) will likely prove insufficient for many NRMM applications. Instead, OEMs will need to consider industrial connectors or electric vehicle supply equipment (EVSE) to provide adequate charging power.

EVSE will likely prove itself among the best connector options as the construction of EV charging station infrastructure continues and fast-charging capabilities become more accessible. Still, opportunity charging may remain more challenging for now.

Multiple Chargers for Greater Power Output

Depending on individual unit capabilities and compatibility, on-board chargers can provide greater power output to replenish larger NRMM batteries by “stacking” multiple chargers or placing them in parallel.

For example, one XV3300 charger (designed and produced by Delta-Q Technologies) provides roughly 3 kW. However, the devices and charging software support the integration of up to three XV3300 chargers, achieving roughly 10 kW.

Aside from the advantage of increasing charger power output, outfitting NRMM with multiple chargers also provides OEMs with greater mounting and configuration flexibility for minimizing space requirements. And multiple-charger systems also achieve redundancy to better ensure NRMM batteries can still charge if one of the devices fails.

Contending with Multiple Battery and Charger Options

Some OEMs may consider offering different sized and power batteries (for more range) and on-board chargers (for faster charging) for the same machine or line of machines. This does introduce significant design and engineering complications:

- Different size batteries or chargers must fit within the same available space.

- Inventory becomes much more complex.

- Additional regulatory compliance efforts and product validation testing will be required.

Again, multiple chargers can help minimize the challenges resulting from these decisions. But NRMM must have the space to mount them first.

Ensure Seamless System Integration with Delta-Q Technologies

Seamless system integration for battery chargers necessitates a partnership with charger design, engineering, and testing experts. OEMs substantially benefit from collaboration with partners that know the ins and outs of determining charger location, power, connectors, number of units, and other considerations.

Delta-Q Technologies not only provides this insight but works with common battery suppliers to ensure compatibility—as denoted by the “Charged by Delta-Q” label. After understanding the application and standard work environment for NRMM, Delta-Q Technologies will guide OEMs through every charger decision to best ensure they deliver the performance operators and fleet managers count on.