Downtime in Mobile Elevated Work Platform (MEWP) rental fleets are costly, yet many causes are preventable. In a recent webinar with IPAF North America, the regional division of the International Powered Access Federation, Mourad Chergui, Senior Product Manager at Delta-Q Technologies, outlined practical strategies for fleet owners and operators to protect batteries, enhance equipment reliability, and improve visibility through connected charging and telematics.

MEWP electrification acceleration places batteries at the center.

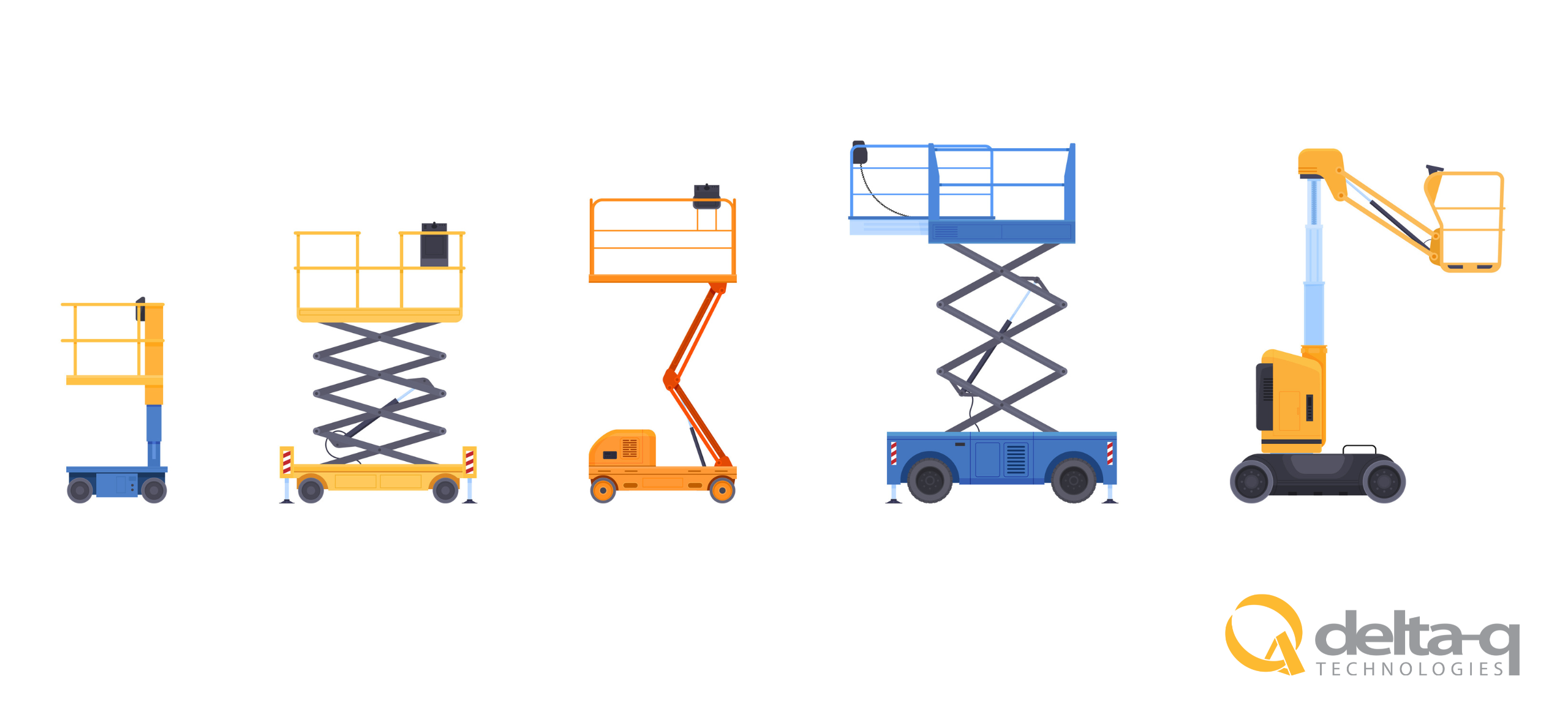

Scissor lifts and compact crawler lifts are among the most electrified segments in MEWPs today, with an ongoing shift toward zero-emission solutions in all other segments. This transition puts a spotlight on the most valuable (and often most expensive) asset in the machine: the battery system.

Lithium-ion batteries are increasingly adopted on MEWP vehicles for their longer cycle life, support for fast and opportunity charging, and reduced maintenance, which can improve total cost of ownership over time. However, lead-acid batteries remain the most used in MEWPs due to their lower upfront cost, reliable performance, and their weight, which serves as a counterbalance in machine design. Fleets may use flooded, AGM, and gel variants, each with specific tradeoffs in maintenance, temperature tolerance, discharge behavior, charging sensitivity and lifetime.

What really kills batteries in the field

The webinar highlighted four recurring modes of premature lead acid battery degradation and shortened lifetime:

- Improper charging: Undercharging, or not completing a full charge cycle, accelerates sulfation and reduces runtime. Overcharging generates excess heat, plate corrosion, and water loss, which is especially damaging for sealed or valve-regulated batteries. A well-matched charging profile and a charger with precise voltage regulation and auto-shutoff feature prolonging lifetime.

- Extreme temperatures: Batteries perform best at approximately 25°C (77°F) ambient temperature. Higher temperatures accelerate corrosion and can significantly reduce battery life. Cold temperatures decrease available capacity and may damage batteries if used below freezing. Chargers with temperature sensing can adjust charging behavior to protect batteries.

- Deep discharge: For lead-acid systems, routinely discharging below approximately 20% state of charge can cause permanent damage especially if combined with leaving the battery in a discharged state for long periods of time. Training and policies that prevent over-draining, along with charging immediately after shifts, are essential.

- Prolonged inactivity (seasonal storage): Lead-acid batteries naturally self-discharge over time. If left unused, sulfation and stratification can permanently degrade capacity. Using chargers with storage modes, maintenance charging, or scheduled recharging can prevent these issues.

“Quality of charge” matters more than just “charger specifications”

A key point is that not all battery chargers are the same, and the charge profile, or algorithm, is critical for battery performance. Purpose-built, battery-specific algorithms developed with battery manufacturers have been proven to provide better runtime and longer battery life. Universal charging profiles may work across multiple battery types but often compromise battery performance and longevity.

Beyond batteries: component quality and durability

Downtime is not only related to batteries. MEWPs operate in harsh environments with exposure to moisture, dirt, oils, solvents, battery acid, UV, shock, and vibration. The webinar emphasizes selecting robust, sealed components, and ensuring equipment and subcomponents are validated through durability testing, including thermal cycling, vibration, and drop tests.

Fleet management and telematics: turning charging data into uptime

Preventive and predictive maintenance improves uptime further — and it starts with data.

Smart chargers log key battery parameters such as voltage, temperature, charge cycles, and fault alerts across hundreds of cycles. That data can be downloaded via USB, shared via Bluetooth, or transmitted through CAN-based communication into vehicle telematics systems for centralized tracking, troubleshooting, and trend monitoring.

When smart chargers are paired with telematics platforms, fleets can better manage assets, schedule maintenance, enable over-the-air updates, and detect patterns early to prevent equipment downtime.

Key takeaways for rental fleets

- Battery life is heavily influenced by charge quality and charging habits — not just battery selection.

- Operator training (charge after every shift, confirm charging starts, avoid deep discharge) helps reduce preventable failures.

- Temperature-aware charging helps protect batteries in extreme climates.

- Connected chargers and telematics provide visibility, enable accountability, and support preventive and predictive maintenance to reduce downtime.

For the full discussion and Q&A, watch the webinar here: