For Mobile Elevated Work Platforms (MEWPs), bigger isn’t always better. This is especially true with battery-powered MEWPs, where advancing technology promises to deliver more power in smaller packages.

Data from the US Office of Energy Efficiency and Renewable Energy (EERE) supports this statement, reporting an eightfold increase in lithium-ion battery energy density between 2008 and 2020.

This shift is revolutionizing power solutions in MEWPs, prompting OEMs, engineers, and fleet managers to reassess their charging strategies to maximize uptime and productivity.

Charging Dynamics of Lead-Acid Batteries

Understanding the efficiencies of a smaller charger starts with comprehending the charging process itself, starting with the lead-acid packs so commonly used in electrified MEWPs.

The charge cycle of lead-acid batteries is divided into three distinct phases:

- Bulk – Delivers high power to the battery, rapidly increasing its charge level until it reaches a specified voltage threshold.

- Absorption – Gradual tapering of charge rate as voltage stabilizes, ensuring that the lead plates fully absorb the charge in preparation for the final phase.

- Finish – A lower current safely maintains the battery at full charge, restoring the plates to their maximum capacity without overcharging.

It must be noted that these phases represent a nonlinear charge trajectory.

For example, consider a scissor lift with a lead-acid battery and an 8-hour overnight charging schedule. To achieve this window, chargers are typically sized to handle the power demands of the Bulk phase, which kickstarts the charge with high voltages.

However, as the battery approaches full charge, the Absorption phase takes significantly longer due to mounting internal resistance. Continuing with the example of our scissor lift, completing the final 20% of the charge would drag on for 4 hours—or half of the total charge time.

Streamlined Charging: The Lithium Battery Advantage

Unlike lead-acid, lithium batteries have several unique characteristics that enable more efficient and effective charging.

First, lithium batteries maintain maximum charging rate for most of the charging cycle. The only exception is a brief cell balancing phase at the end of the charging process, which is managed by the Battery Management System (BMS).

Second, lithium operates with exceptional efficiency, especially within a charge range between 10% to 90% of their total capacity.

Last, lithium batteries charge linearly—the percentage increase in charge is directly proportional to charging time. This linearity is the crucial lynchpin that brings us back to our main theme: downsizing chargers.

The Potential of Compact Chargers

Understanding lead-acid and lithium charging processes lays an essential foundation for appreciating why smaller chargers can be just as effective—if not more so—across MEWP applications.

To illustrate, let’s return once more to our example of a battery-powered scissor lift:

- Lead acid – A standard 4x6V (24V 220Ah) lead-acid battery pack typically requires a 700W charger to recharge overnight from 0% to 100%.

- Lithium – Remarkably, an equivalent lithium pack (24V 180Ah) can achieve the same overnight charge (from 10% to 90%) using just a 350W charger.

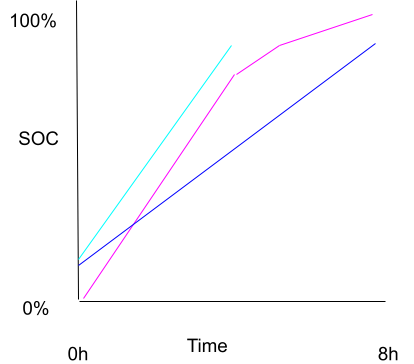

This doubled efficiency stems from the linear charging profile of lithium batteries compared to the nonlinear nature of lead-acid batteries. Consider the following chart to better visualize this:

- The purple line represents the lead-acid charge progress overnight from 0% to 100% at approximately 700W.

- The light blue line shows a lithium charge from 10% to 90% using the same power charger, completing in approximately half the time.

- The dark blue line demonstrates a lithium charge from 10% to 90% using a 350W charger, taking the same time as the lead-acid charge but with just half the power.

Advantages of Adopting Smaller Chargers in MEWP Applications

As the chart and example illustrate, lithium batteries and chargers open up new possibilities in MEWP applications:

- Space efficiency – Compact chargers like Delta-Q Technologies’ RQ350 are easier to fit in tight spaces, making them ideal for compact MEWPs with limited room for components.

- Versatility – A smaller charger can be used across a wider range of battery sizes, from 2x12V packs to smaller 4x6V packs, providing flexibility in fleet management.

- Cost savings – By matching the charger size to the actual needs of the lithium battery, energy waste is minimized, leading to lower operating costs.

- Simplicity and portability – Smaller chargers are typically lighter and more portable, making them easier to handle and deploy in different environments.

By integrating smaller, more efficient chargers into their designs, OEMs and fleet owners stand to minimize total cost of ownership (TCO) and attract customers looking for sustainable, efficient solutions.

Boosting MEWP Operations by Downsizing

The contrasting charging profiles of lead-acid and lithium batteries reveal that smaller chargers, like the Delta-Q RQ350, can significantly enhance MEWP operations.

By understanding and leveraging the unique nature of these charging processes, OEMs and fleet managers can enjoy faster, more efficient charging cycles without compromising on battery life or performance.

As the MEWP industry transitions towards an all-electric future, the need for optimized charging solutions will only continue to grow.

Delta-Q is poised to support this shift with innovative charging solutions like the RQ-Series, algorithmically-optimized to meet the needs of battery-powered equipment—from lead-acid to lithium-ion and every chemistry in between.

Sources:

The Office of Energy Efficiency and Renewable Energy (EERE). Volumetric Energy Density of Lithium-ion Batteries Increased by More than Eight Times Between 2008 and 2020. https://www.energy.gov/eere/vehicles/articles/fotw-1234-april-18-2022-volumetric-energy-density-lithium-ion-batteries

Delta-Q Technologies. What is an Algorithm / Charge Profile? https://support.delta-q.com/hc/en-us/articles/360015387312-What-is-an-Algorithm-Charge-Profile

Battery University. BU-403: Charging Lead Acid. https://batteryuniversity.com/article/bu-403-charging-lead-acid%C2%A0