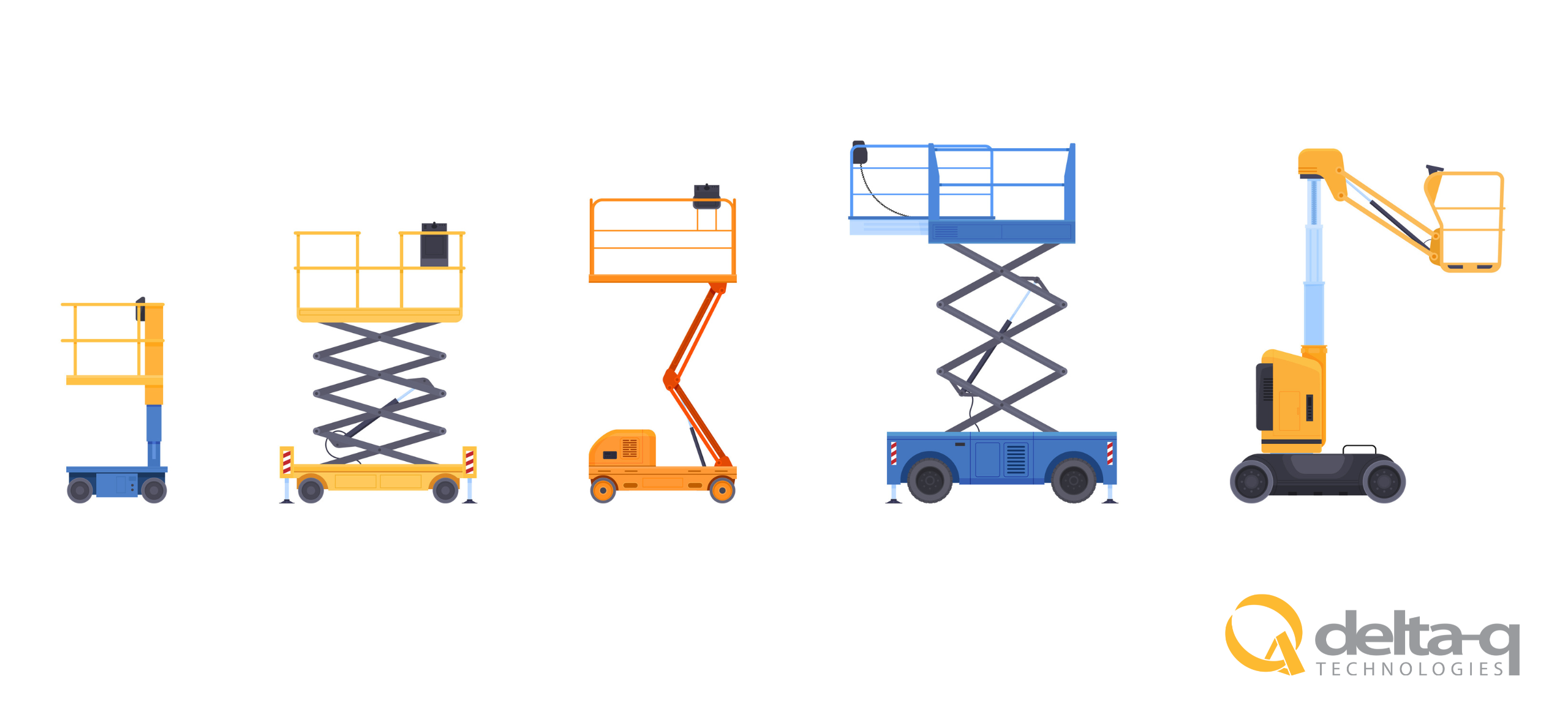

From construction equipment to mobile elevated work platforms (MEWP), the electrification of heavy-duty, non-road machinery continues reshaping industries. But what truly powers this transition?

While regulations and sustainability goals provide the initial push, the real momentum comes from technological advancements. Each innovation breaks down barriers to widespread adoption, making electrified machinery more efficient and viable for original equipment manufacturers (OEMs) and operators.

In the recent ZAPI GROUP webinar, Powering Progress: Innovations in Charging Solutions for Off-Highway Mobile Machinery, Rod Dayrit delves into four innovations driving this electric transition.

By understanding the trends behind these innovations, OEMs position themselves to navigate electrification as efficiently as possible.

Innovation #1 – Integrating Chargers with System-Level Components

Throughout the webinar, Dayrit emphasized the critical role of charging systems as the cornerstone of electrified machinery. The reason? Optimized chargers extend the value of a machine’s most important (and expensive) component: the battery.

By integrating the charger with system-level components, OEMs unlock synergistic efficiencies otherwise unattainable in internal combustion engines (ICE). A fully realized “4-in-1” integration represents the pinnacle of such systems, combining components such as:

- On-board chargers

- DC-DC converters

- AC export power

- EVSE interfaces

Although such a “package solution” remains on the horizon, partial integrations already drive significant advancements. Strategically condensing packaging and circuitry lowers production costs, improves energy efficiency, and simplifies assembly. This also enables OEMs to delegate much of the integration work to specialized suppliers and third-party integrators, alleviating developmental burden while accelerating time-to-market.

Innovation #2 – On-Board Chargers with Electric Vehicle Supply Equipment (EVSE) Compatibility

Building on the first innovation, integrating on-board chargers with an EVSE-compatible interface represents a pivotal step for electrified industrial machinery. EVSE—commonly known as public EV charging stations—enjoys a rapidly expanding global market, projected to nearly double in size between 2023 and 2030.

To leverage this growing infrastructure, OEMs must incorporate electric vehicle communication controllers (EVCC) into an on-board charging solution. This essential component bridges the communications gap between electrified equipment and EVSE infrastructure, negotiating fast, reliable, in-the-field charging for even heavy-duty construction equipment.

Not only does EVCC allow for opportunistic fast charging, but it also enables compatibility with the overall charging pile:

- Level 1, 120 V charging – Allows for the charging of electrified equipment through standard wall outlets, greatly expanding OEM charge options in residential worksites.

- Level 2, 240 V charging – Available in commercial and some residential settings, improving charge speed.

- Level 3, 480 V DC fast charging – Typically reserved for EVSE and commercial use, cutting charge time from hours to minutes.

Innovation #3 – Progress in Power Electronics

Another bottleneck to electrifying off-road machinery lies with inherent power limitations. Electric motors struggle to deliver the same raw power density as their ICE counterparts, limiting adoption in industrial sectors.

Advancements in power electronics, however, promise to overcome these barriers.

Emerging materials like gallium nitride (GaN) and silicon carbide (SiC) deliver efficient solutions tailored to the unique demands of industrial machinery, far outperforming traditional silicon-based power electronics.

For example, SiC-based semiconductors demonstrate impressive parameters such as:

- The ability to handle voltages up to 1.2 kW, essential for high-powered applications

- 250% higher thermal conductivity compared to silicon, enabling more compact designs

- 47.5% lower power losses on average compared to silicon, improving system efficiency

SiC thus represents the current best-in-market solution for power electronics, ideal for industrial electrification due to its reliability and efficiency when handling higher voltages.

GaN builds on the advantages of SiC with even greater efficiency and power density, making it particularly well-suited for low- to mid-voltage applications. Specifically, GaN’s performance benefits include:

- Over 95% efficiency, with 50% lower power losses versus silicon

- Capable of handling voltage levels up to 600 V

- 10x faster electron mobility versus silicon, improving overall performance

With lower manufacturing costs compared to SiC, GaN-based semiconductors offer an attractive balance between performance and affordability, particularly for applications in the 600 V range.

Innovation #4 – Remote Integration Technologies

Lithium-ion batteries continue to expand across market verticals—and for good reason. While lead-acid chemistries paved the way for electrification and remain a reliable option, only lithium-ion unlocks advanced communications technologies.

In tandem with an intelligent battery management system (BMS), internal efficiencies can be optimized in real time between components. Consider a few examples:

- CAN bus protocols communicate with external sensors and the BMS to alter charging parameters in response to external elements, ensuring optimal performance.

- A BMS monitors and logs a vehicle’s usage patterns, allowing OEMs to develop charging profiles and algorithms that maximize charge speed and battery longevity.

- The charger’s BMS and CAN communication work together to detect potential safety issues, such as overheating or overvoltage, and adjust operations to prevent damage.

Beyond internal systems, a lithium-ion platform and integrated BMS facilitate external communication with fleet management platforms. This allows fleet managers to have real-time access to critical data, such as work duty cycles and charging parameters, to enable data-driven strategies.

For example, OEMs might establish first-in-first-out (FIFO) battery queues, ensuring balanced usage across the fleet to simplify maintenance scheduling and further extend battery life.

Integration: The Underlying Driver of Each Innovation

Each of these four innovations has one unifying factor: integration. Off-highway machinery demands ever-increasing power, voltage, and connectivity—and seamlessly integrated solutions stand out as the next logical iteration.

Such holistic platforms deliver tangible benefits, such as:

- Streamlined logistics – Package solutions simplify manufacturing and assembly, reducing production costs and cutting down on unnecessary complexity.

- Improved versatility – Integrating BMS and similar charging platforms broadens charging options and facilitates data-gathering to refine future strategies.

- Shared development – Distributing the challenges of integration across suppliers allows OEMs to focus on market differentiation.

As electrification advances, integration may well become the defining factor for OEMs seeking to sharpen their competitive edge.

Powering Progress to an Electrified Future

Dayrit concluded the webinar by highlighting the value of partnering with electrification experts—such as the ZAPI GROUP of companies—to streamline their transition and shift developmental burdens down the supply chain.

As a member of the ZAPI GROUP, Delta-Q Technologies proudly contributes to the global electrification movement. With years of experience in developing and iteratively testing charging solutions designed for the rigors of industrial sectors, Delta-Q Technologies, along with the ZAPI GROUP, stands ready to support OEMs across industries in their electrification journey.