Mobile Elevated Work Platforms

Delta-Q’s scissor and boom lift lithium and lead-acid battery chargers have earned a global reputation for charge quality, integration support, reliability and robustness under difficult charging conditions.

Learn MoreMinimize the risk of premature battery and charging failure, reduce total cost of ownership, and maximize machine uptime with our charging solutions.

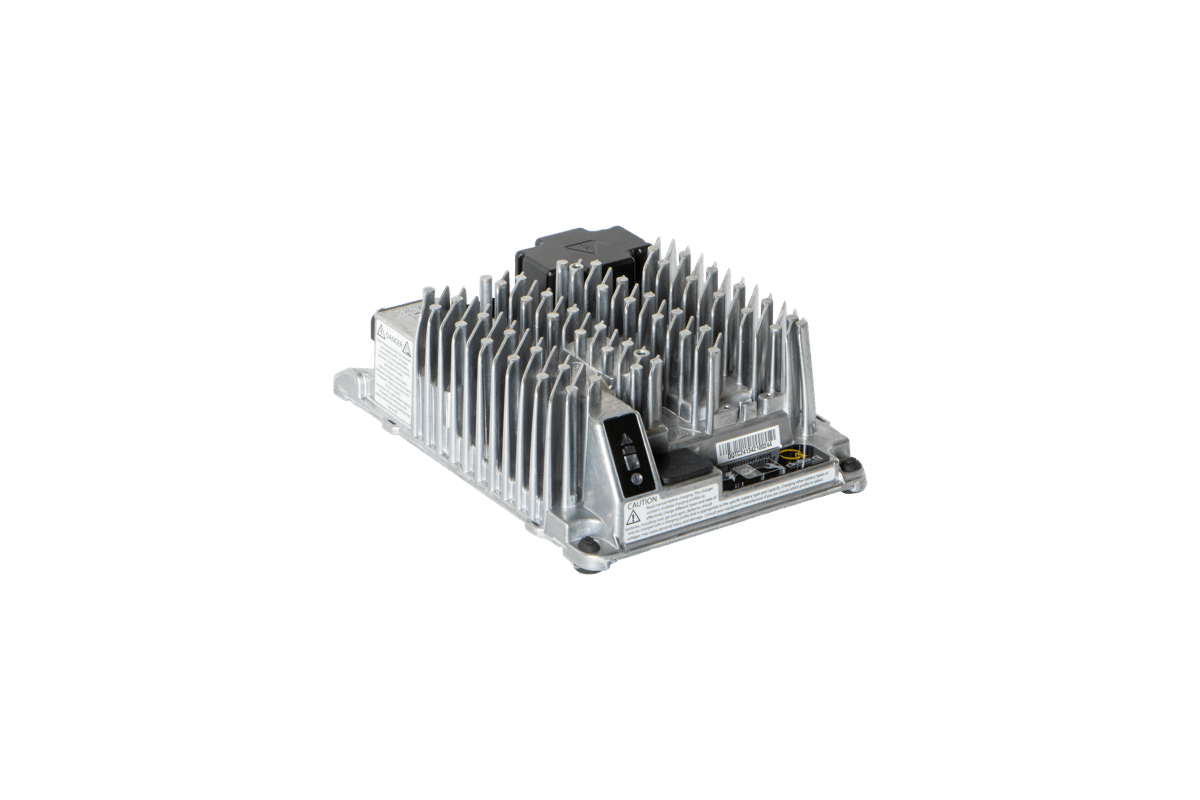

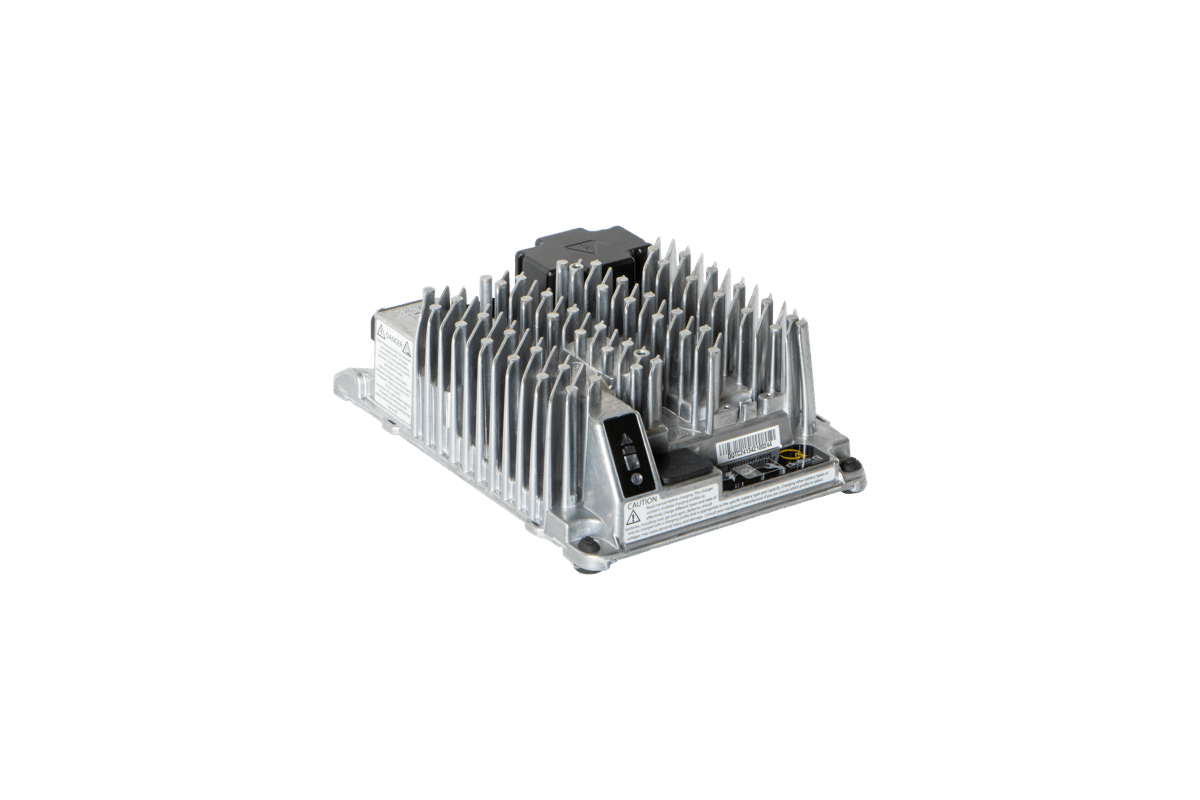

The IC Series hardware architecture was engineered on the principle of design and manufacturing reliability. With a streamlined assembly, the charger is designed for manufacturing success, avoiding potential defects and subsequent project delays.

The IC Series provides charge quality for different lead-acid battery chemistries (wet/ flooded, sealed AGM or gel) or can support lithium charging via CAN bus communication. A button on the charger’s display enables the easy selection of another pre-loaded charge algorithm, providing flexibility for service technicians.

Optional CAN bus communication enables a link between the IC series chargers and other components for safe lithium charging and the built-in USB host port allows for downloading charge cycle data, updating charger software or charge algorithms, and to pull machine diagnostics and servicing information.

Learn more about each product in our IC Series family of chargers here. We work with you to find the right charger configuration and assist with the integration, training, and servicing.

More Details

| 24V Model | 36V Model | 48V Model | |

|---|---|---|---|

| Max DC Output Power | 650 W | 650 W | 650 W |

| Max DC Output Current | 27.1 A | 18.1 A | 13.5 A |

| AC Input Voltage Range | 85-270 VAC | 85-270 VAC | 85-270 VAC |

| Battery Type | Lead-Acid (Wet / AGM / Gel) & Lithium | Lead-Acid (Wet / AGM / Gel) & Lithium | Lead-Acid (Wet / AGM / Gel) & Lithium |

| All Models | |

|---|---|

| Dimensions | 25.2 x 18.6 x 8 cm / 9.9 x 7.3 x 3.1” |

| Weight | 3 kg / 6.5 lbs |

| Cooling | Normal operation in any orientation with passive cooling |

| IP Protection | IP66 |

| All Models | |

|---|---|

| Efficiency | 93% peak efficiency; California Energy Commission (CEC) and Department of Energy (DOE) compliant |

| Safety | UL1564, CSA 107.2, EN 60335-2-29, AZ/NZS60335 (RSM) |

| Emissions | FCC Part 15 / ICES 003 Class A, EN55011, EN 61000-6-4 |

| Immunity | EN 61000-3-2, EN 61000-3-3, EN 61000-6-2 |

More Details

| 24V Model | 36V Model | 48V Model | |

|---|---|---|---|

| Max DC output Power | 900 W | 900 W | 960 W |

| Max DC Output Current | 37.5 A | 25.0 A | 20.0 A |

| AC Input Voltage Range | 37.5 A | 25.0 A | 20.0 A |

| Battery Type | Lead-Acid (Wet / AGM / Gel), Lithium | Lead-Acid (Wet / AGM / Gel), Lithium | Lead-Acid (Wet / AGM / Gel), Lithium |

| All Models | |

|---|---|

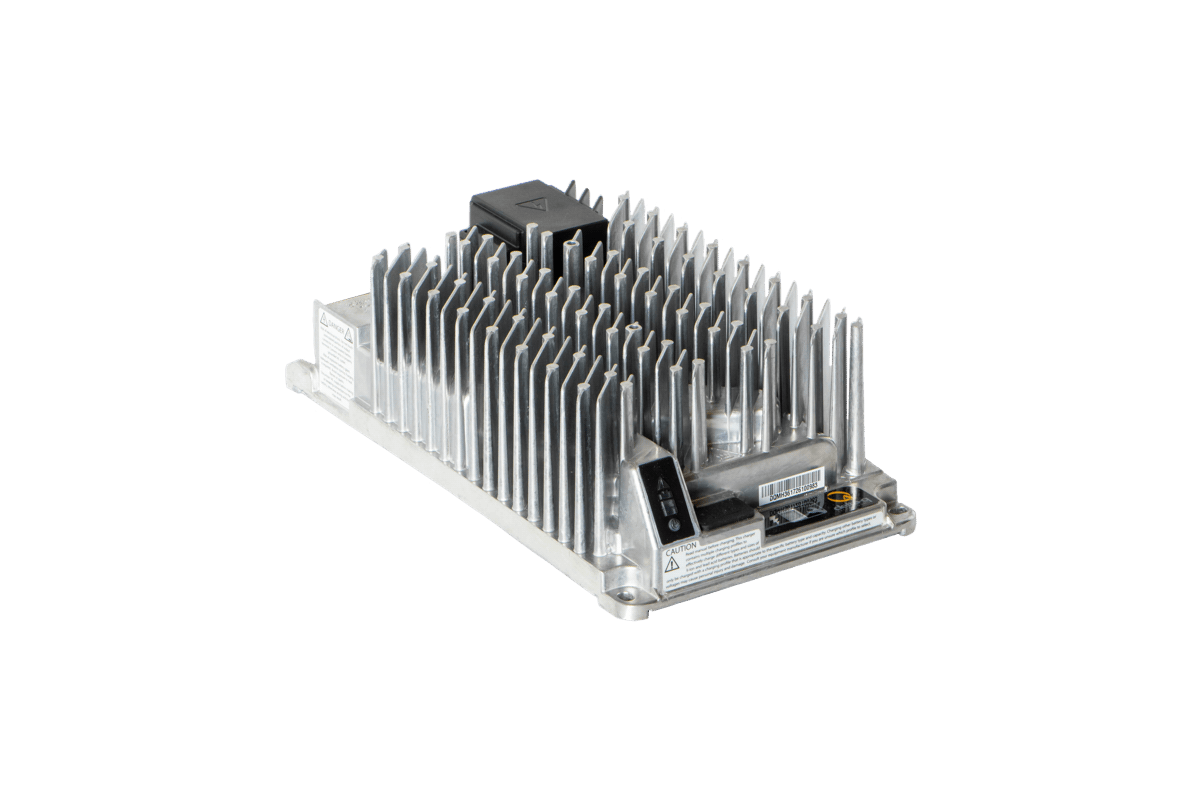

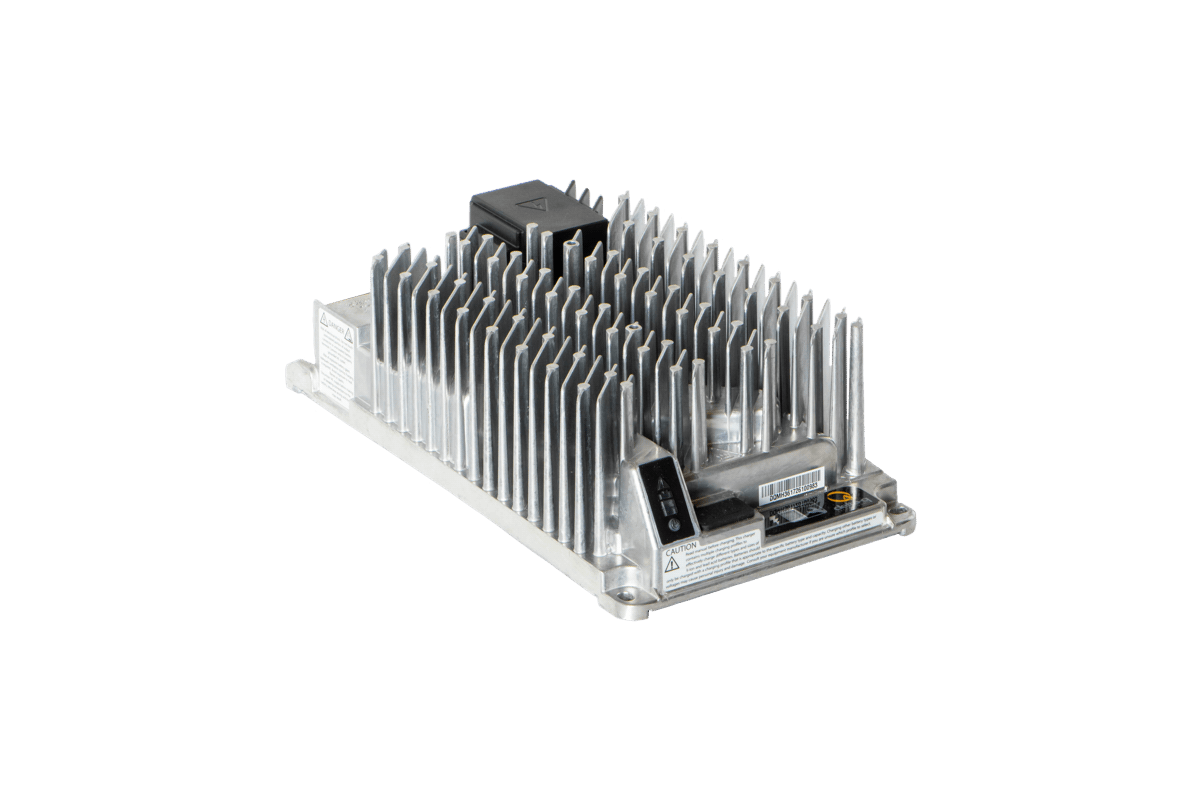

| Dimensions | 33.5 x 17.9 x 10.2 cm / 13.2 x 7.0 x 4.0″ |

| Weight | 4 kg / 9.6 lbs |

| Cooling | Convection cooled |

| IP Protection | IP66 |

| All Models | |

|---|---|

| Efficiency | 90% at full load, 120 VAC, 48 VDC | 92% at full load, 240 VAC, 48 VDC California Energy Commission (CEC) standards compliant |

| Safety | UL1564, CSA 107.2, EN 60335-2-29 |

| Emissions | FCC Part 15 / ICES 003 Class A, EN55011, EN 61000-6-4 |

| Immunity | EN 61000-3-2, EN 61000-3-3, EN 61000-6-2 |

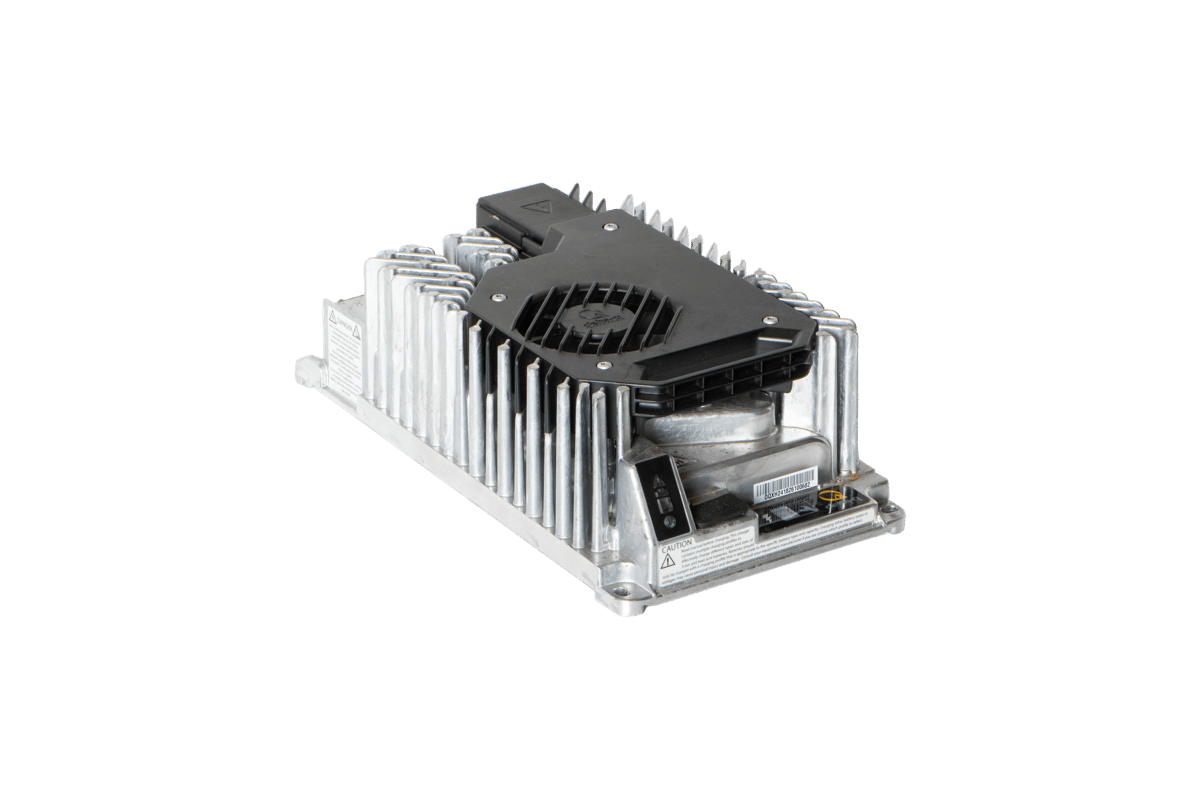

More Details

| 24V Model | 36V Model | 48V Model | |

|---|---|---|---|

| Max DC output Power | 1200 W | 1200 W | 1200 W |

| Max DC Output Current | 50.0 A | 33.3 A | 25.0 A |

| AC Input Voltage Range | 85-270 VAC | 85-270 VAC | 85-270 VAC |

| Battery Type | Lead-Acid (Wet / AGM / Gel), Lithium | Lead-Acid (Wet / AGM / Gel), Lithium | Lead-Acid (Wet / AGM / Gel), Lithium |

| All Models | |

|---|---|

| Dimensions | 33.5 x 17.9 x 10.5 cm / 13.2 x 7.0 x 4.1″ |

| Weight | 4.1 kg / 9.0 lbs |

| Cooling | Active cooling with fan (variable speed, field serviceable, field replaceable) |

| IP Protection | IP66 |

| All Models | |

|---|---|

| Efficiency | 90% at full load, 120 VAC, 48 VDC | 92% at full load, 240 VAC, 48 VDC California Energy Commission (CEC) compliant |

| Safety | UL1564, CSA 107.2, EN 60335-2-29 |

| Emissions | FCC Part 15 / ICES 003 Class A, EN55011, EN 61000-6-4 |

| Immunity | EN 61000-3-2, EN 61000-3-3, EN 61000-6-2 |

Build an electric drive product with better flexibility and longevity with our battery charging solutions, all developed with your needs in mind.

Clear seven-segment display indicates charging progress and completion, errors, faults, status and data.

Easily switch between charge algorithms for lead-acid (wet/flooded, sealed AGM or gel) battery chemistries and different brands with a touch of a button, providing greater flexibility for service technicians.

The USB host port allows for easy factory or field configuration, algorithm/software update, and charge cycle data downloading.

The IC Series have a common width, enabling seamless upgrading for larger packs or faster recharge times and can be configurable to fit multiple machines for worldwide deployment with minimal SKUs.

Support charge cycle data analysis across multiple chargers and battery packs for advanced fleet management with the IC Series data analysis tool.

Capable of operating reliably on any single-phase grid worldwide, the IC Series is highly efficient, leading to electricity savings and shorter charge times.

Benefit from over 23 years of engineering innovation, quality and product performance with Delta-Q’s battery chargers, the solution of choice for tier one OEMs.

Delta-Q’s scissor and boom lift lithium and lead-acid battery chargers have earned a global reputation for charge quality, integration support, reliability and robustness under difficult charging conditions.

Learn MoreDelta-Q’s on- and off-board charging solutions provide electric golf vehicles the ideal combination of flexibility and uninterrupted performance.

Learn MoreLithium battery solutions with on-board charging and telematics capabilities are revolutionizing traditional lift trucks and other material handling equipment. Delta-Q understands these needs and our chargers provide safe and reliable charging for lithium battery systems.

Learn MoreFind and download product-specific information here.

Find the perfect battery and charger combination to provide your products with best-in-class performance, prolonged battery life, and maximum up-time with Charged by Delta-Q.

Can’t find the right charger and battery combination? Contact our team for a free consultation!